What is schedule 80 Pipe?

Pipes are globally identified based on outside pipe diameter (OD), Inside diameter (ID), it’s wall thickness (WT), and weight.

This is made simple because of pipe Schedule numbers. Knowing how Pipe Schedules & Nominal Pipe Sizes (NPS) work is very helpful for fabricators, inspectors, foremen, and engineers.

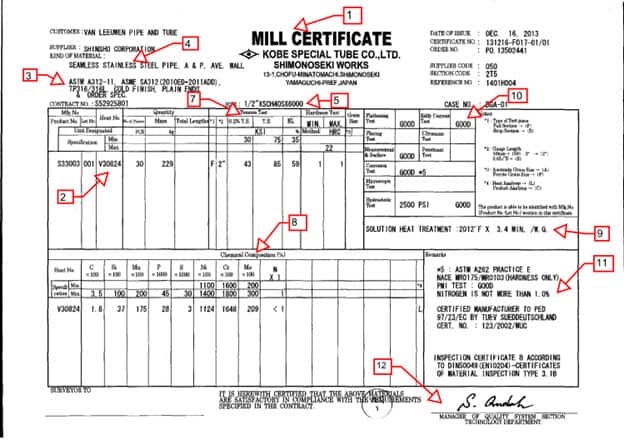

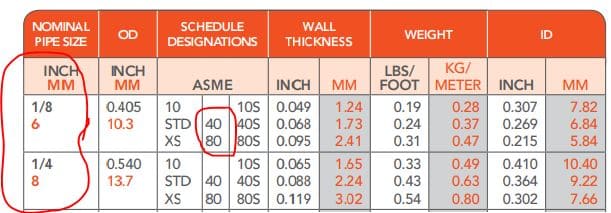

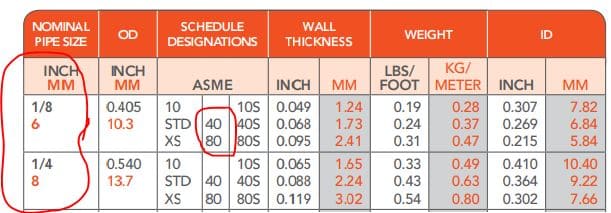

In a Pipe Schedule Chart, you need to know the nominal Pipe Size (NPS) first, and then the pipe Schedule. Based on these two pieces of information, you can know the pipe wall thickness, its weight and ID as shown in the below picture.

Schedule 80 pipe is that is made to have a thicker wall than schedule 40 pipe as you can see in the below example for 1/8 inch (6 mm) & 1/4 inch (8 mm) nominal pipe size. This makes it stronger and more durable to withstand higher pressure per square inch (PSI).

For Different nominal pipe sizes, the wall thickness varies for Schedule 40 & 80 pipes. But, Schedule 80 wall thickness is always higher than the Schedule 40 pipe.

In the above picture, you will see the thickness for:

- Schedule 40 1/8 inch is 0.068 inch & Schedule 80 1/8 inch is 0.095 inch.

- Schedule 40 1/4 inch is 0.088 inch & Schedule 80 1/8 inch is 0.119 inch.

Schedule 80 pipe is often used in industrial applications where extra strength is necessary such as oil & gas plants, chemical plants & power plants.

What is Schedule 40 Pipe?

Schedule 40 Pipe is a standard Steel pipe size that is most commonly used in industrial pipelines, plumbing and drainage applications.

The Pipe Schedule is applicable for Steel pipes only as for other metals, the density will vary and the Schedule chart will not be applicable.

Schedule 40 Pipe is available in diameters from 1/8 inch to 34 inches. Click here to download Pipe Schedule Chart.

Schedule 80 vs 40 Pipe

When it comes to piping, there are different types of Pipe Sizes & Materials you can choose from. The two most popular

Pipe sizes are schedule 80 and schedule 40 pipes. In this article, we will compare and contrast the schedule 80 and schedule 40 pipes to help you decide which one is right for your next project.

The main differences between Schedule 80 and Schedule 40 pipe are:

- Pipe Wall Thickness

- Pipe weight

- Inside Diameter of the pipe

- Schedule 80 and Schedule 40 pipes have different pipe wall thicknesses, different inside diameters & overall weights, with schedule 80 having a thicker pipe wall.

- This makes it more durable and capable of carrying more pressure (Pounds per square inches-PSI) than schedule 40.

- However, schedule 40 is less expensive and easier to work with, so it is often used in residential applications. Schedule 80 pipe is also more expensive and heavier than Schedule 40.

- Schedule 80 has a higher corrosion allowance compared to Schedule 40 due to higher wall thickness, thus Schedule 80 has a higher service life.

Schedule 40 pipe is made of a thinner material than schedule 80 pipe. This makes it less durable and less likely to withstand pressure.

However, it is cheaper and easier to work with, making it a better choice for projects that don’t require as much durability.

Schedule 40 vs 80 steel pipe thickness

The thickness of Schedule 80 is always higher than Schedule 40 Pipe. Different Nominal Pipe Sizes (NPS) has different steel pipe thickness based on the NPS size. So, the thickness of different Schedule 40 & 80 pipes varies based on the NPS.

You can easily find the thickness of a nominal pipe size & corresponding Schedule Number using the Pipe Schedule Chart.

Schedule 40 vs Schedule 20 Pipe

schedule 40 and schedule 20, Both have their pros and cons, but which one is right for you?

Schedule 40 pipe is thicker and can handle more pressure than the schedule 20 pipe. This makes it a better choice for projects that require a lot of strength, such as gas lines or water mains. Schedule 40 pipe is also more expensive than schedule 20 pipe.

Schedule 20 pipe is thinner and can’t handle as much pressure as the schedule 40 pipe. It’s ideal for projects that don’t require a lot of strength, such as drainage systems or sprinkler systems. Schedule 20 pipe is also less expensive than schedule 40 pipe.

What is Schedule 40 Pipe Used For?

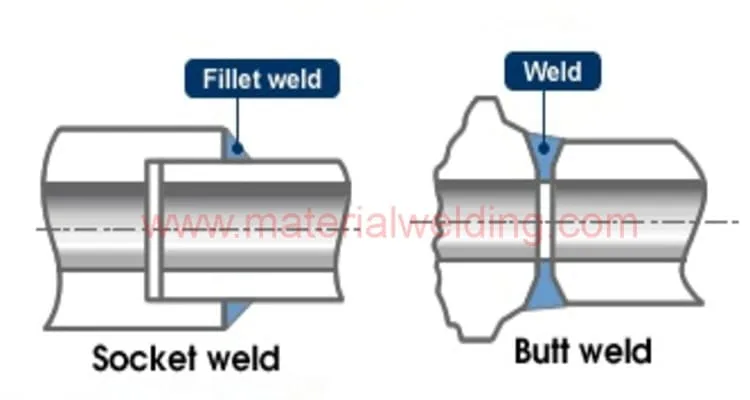

Schedule 40 pipe is a type of piping that is used for a variety of purposes. It is made from steel or other metals or PVC, and has a thickness based on Nominal Pipe Size (NPS).

This type of pipe is often used for transporting water, gas, or oil. It can also be used for plumbing, drainage purposes or in irrigation systems.

Schedule 40 pipe is strong and durable, and can withstand high pressure levels compared to pipe of same NPS with lower Schedule number.

What is Schedule 80 Pipe Used For?

Schedule 80 pipe is a type of metal pipe that is used for a variety of purposes, including transporting water and other liquids, as well as gas.

Schedule 80 pipe is a type of steel piping that is commonly used in high-pressure and high-temperature applications.

It has a thicker wall than other types of steel pipe, making it more resistant to wear and tear. Schedule 80 pipe is also less likely to deform under pressure, making it a good choice for critical applications.

This type of pipe is often used in industrial settings or for larger projects where greater strength and durability are required.

Schedule 40 vs 80 PVC Dimensions

Schedule 40 vs 80 PVC Dimensions depend on the nominal Pipe size (NPS). The lower the NPS, smaller the PVC pipe thickness & weight.

Can you mix Schedule 40 and Schedule 80 PVC?

Both Schedule 40 PVC & Schedule 80PVc has same outside diameter (OD). So it is possible to interchange Schedule 40 PVC & Schedule 80PVC.

Which is stronger schedule 40 or 80?

When it comes to pipes, there are two main types: schedule 40 and schedule 80. Both have their benefits, but which one is stronger?

Schedule 40 is made up of thinner pipes than schedule 80, meaning that it’s not as strong but also lighter and less expensive.

Schedule 80, on the other hand, is made up of thicker pipes and is stronger but also heavier and more expensive.

In general, schedule 80 is the better option if you need a pipe that is strong and durable. However, if you are looking for something that is lightweight and affordable, schedule 40 may be the better choice for you.