Importance of Welding Cost Calculation

The cost elements of a welded part are those related to materials, labor, and overhead. Only welding materials such as filler metals, gases, and welder manhour rates are considered in this article.

If you wish to include overhead cost or any additional cost then it needs to add separately to the total welding cost calculated here.

Welding cost calculation is an important step in the welding process. It helps to identify the cost of each weld and determines the feasibility of a particular weld. The calculation also takes into account factors such as the time required for welding, the type of welder (Machine) used, and the cost of labor.

The welding cost calculation can be done manually or with the help of a software program. In either case, it is important to ensure that all the relevant data is included in order to get an accurate estimate.

The reasons for costing welding are varied, but most often are to:

- Provide data needed for bidding on a job

- Compare the economics of welding with some other method of fabricating or manufacturing

- Establish information required in making a decision between alternate designs

- Evaluate proposed changes in procedures

- Compare the economic advantages of competing welding processes.

Steps for Welding Cost Calculation:

- Consider the joint geometry for every joint type.

- Break the weld into simple geometrical shapes. E.g., a groove weld is made up of two insolence triangles and one rectangle. This is helpful for welding area & volume calculation.

- For each type of weld, choose the “excess weld factor” (X%). (You can group welds by size).

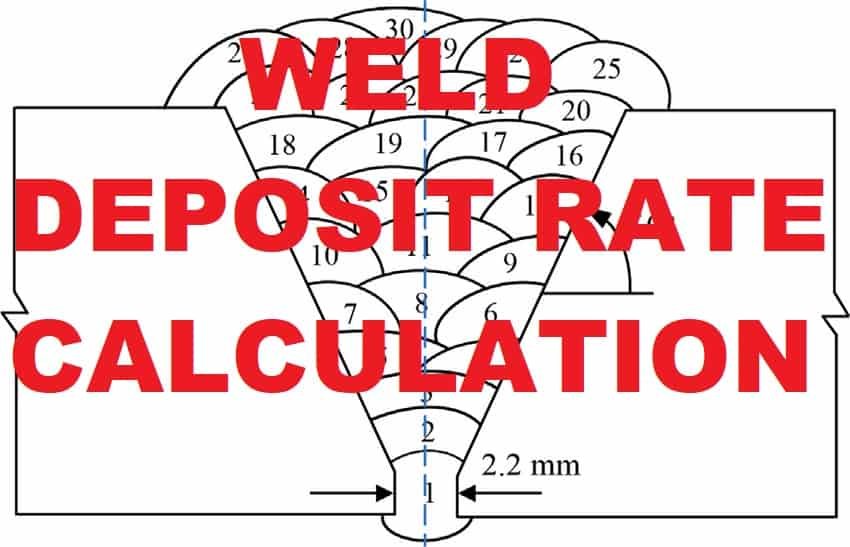

- Calculate the “Weld Metal Deposition Rate” (D) based on the welding process, electrode, and average current range (take help from WPS).

- Calculate the “Welder/Operator Work Efficiency Factor” (Dw) (more details in the link).

- Determine “Weld Process Deposition Factor” (Dp). Also called Welding Efficiency factor.

1. Determine the total cross-section area for different welds:

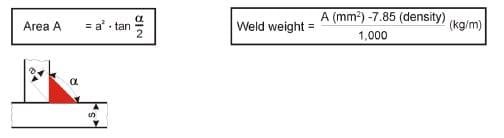

The cross-section area of a weld is the area of the metal that will be melted during the welding process. This area can be determined using a calculation.

The cross-sectional area of a weld is determined by its shape and size. A simple calculation can be used to determine the area of a rectangle or square. For other shapes, such as circles or ovals, more complicated calculations are necessary.

The First step is to calculate the total cross-section area of the weld as given below:

At = A X (100 + X)/100

Where:

A = Theoretical weld cross-section area

X = Extra weld because of oversize and weld surface reinforcement (in %)

At = Total cross-section area of the deposited weld (includes excess weld)

2. Calculate the Volume of Weld Deposited:

V = At ×L

Where L = Weld Length (or total length of similar welds).

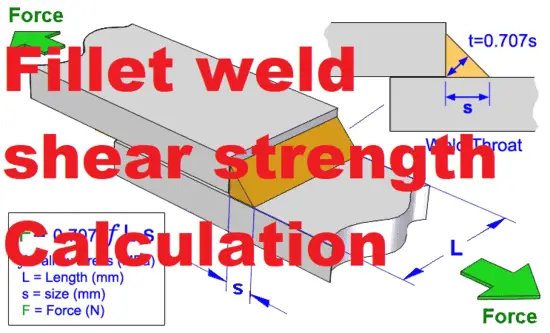

The Fillet Weld volume calculation is fairly simple once you have all of the measurements. First, you need to calculate the area of the fillet weld based on throat size using the formula given below.

Then, multiply two measurements i.e. area & weld material density together to get the total volume or Weld Weight of weld material required as explained below.

Alternatively one can refer to the electrode manufacturer for the number of electrodes required to deposit 1 kg of weld-metal or the weight of weld-metal obtained from each electrode.

3. Calculate the Weight of Weld (W):

W = V×M

Where,

V = Deposited weld metal volume, including the excess weld metal.

W = Weight of deposited weld metal for length ‘L’

4. Determine Welding arcing time in hours (To find shielding gas consumption & cost)

Tw = W/D

D = Weld metal deposition rate per hour.

5. Calculated Total Welding person-hours:

Tt = W/D x Dw

Where Dw = Welder/Operator work efficiency factor (arc time per hour expressed in decimal format)

6. Calculate electrode weight:

E= W/Dp

Where, Dp = Weld process deposition factor {(wt. of metal deposited) / (wt. of electrode used)}

7. Calculate gas consumption:

G = Tw x (cu volume/hour)*

8. Total Welding Cost:

With the above calculations, now we are having the:

- Total weight of weld

- Total manpower hours required for welding

- Shielding gas consumptions

we can find the cost of each item from 1 to 3 by multiplying by the cost of welding wire, cost of manpower, and cost of shielding gas. The total of these three factors will give the total cost of the welding.

The cost of the materials being welded is a key factor in determining the total welding cost. For example, aluminum is more expensive than steel. The type of joint also affects the cost. A fillet weld is less expensive than a butt weld.

Labor costs are another important factor in determining the total welding cost. The rate for welder’s wages will vary depending on geographic location, skill level, and experience.

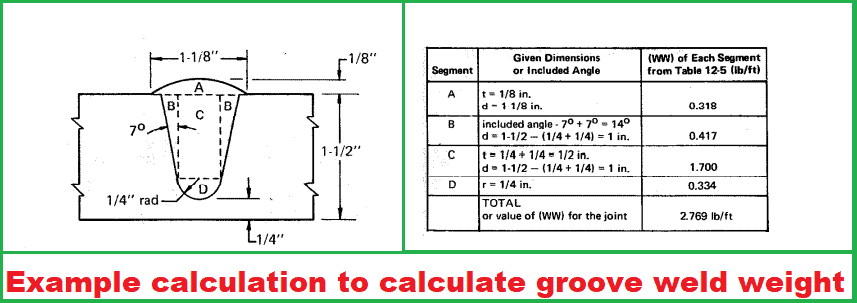

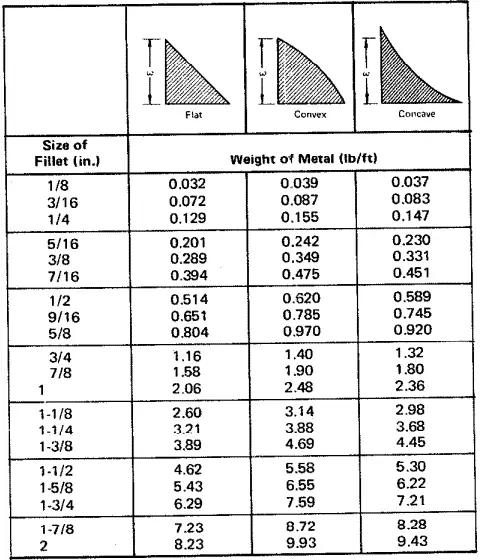

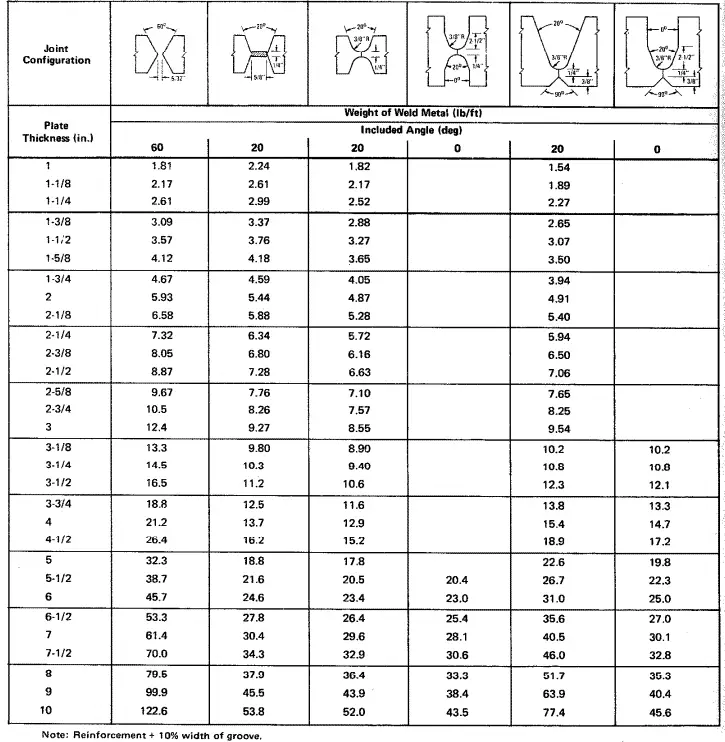

References for Groove Weld & fillet weld weight

The below table provides the Weight of Steel Weld Metal for Fillet Joints. You can find out the weight of flat, convex, and concave fillet welds for sizes given here.

Just multiply the length of the weld with the weight given below. For example, 5 feet length of 1/8 inch flat fillet weld weight will be:

Total weight: 0.032 X 5= 0.16 Pounds

Similarly, the weight of groove welds is given in the below table:

Similar Posts: