Understanding how to calculate the shear strength of a fillet weld is crucial to ensure the safety and durability of your welds. In this article, we’ll explore the fundamentals of fillet weld shear strength calculation, the factors that influence it, and practical examples to help optimize your welding projects.

What is a Fillet Weld?

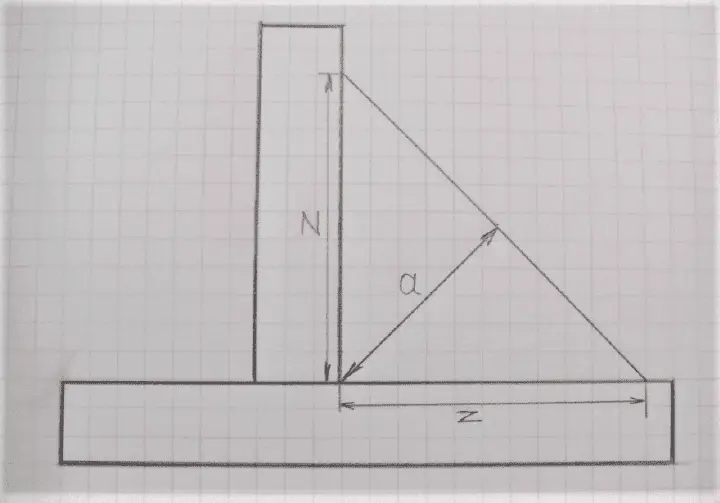

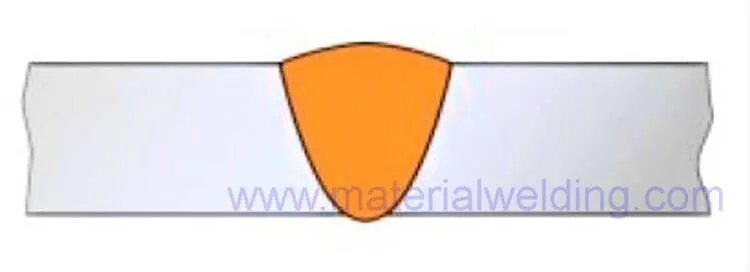

A fillet weld is a type of weld used to join two parts at a right angle. It’s formed by depositing filler material in the shape of a triangle along the joint between the two parts.

Fillet weld shear strength

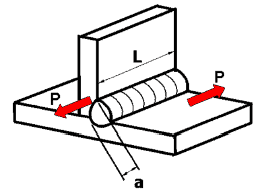

Shear strength refers to the ability of a material or joint to withstand forces that act parallel to its surface. In the case of fillet welds, this means the ability of the weld to resist sliding or pulling apart under load.

Calculation of shear strength requires knowledge of both the size and shape of the fillet weld as well as properties like yield and tensile strength.

It is crucial for engineers and designers to understand how different parameters affect the shear strength of fillet welds. This includes factors such as welding size (fillet weld throat size), electrode strength, material thickness, and weld soundness.

Factors such as the thickness and length of the weld also affect its shear strength. Weld quality plays a significant role in determining the shear strength of fillet joints; hence, proper welding procedures must be followed to ensure optimal performance.

Fillet weld shear strength Calculation

Fillet weld shear strength is a critical factor in mechanical engineering, as it determines the load-carrying capacity of welded structures.

A fillet weld is a type of welding joint that forms an angle between two metal surfaces, and its strength is influenced by several factors such as material properties, weld size, and geometry.

Related reading: how-to-calculate-throat-size-of-fillet-weld

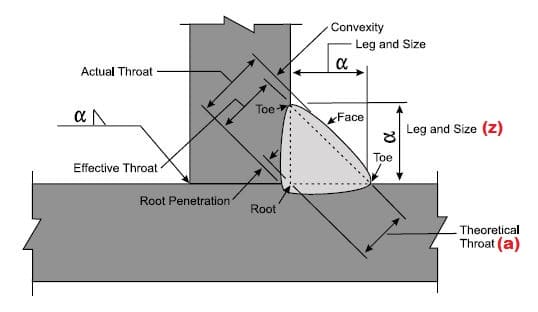

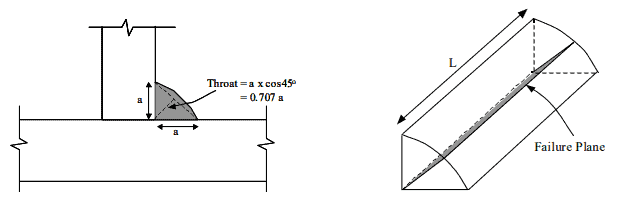

The calculation of fillet weld shear strength involves determining the effective throat thickness and multiplying it by the length of the weld.

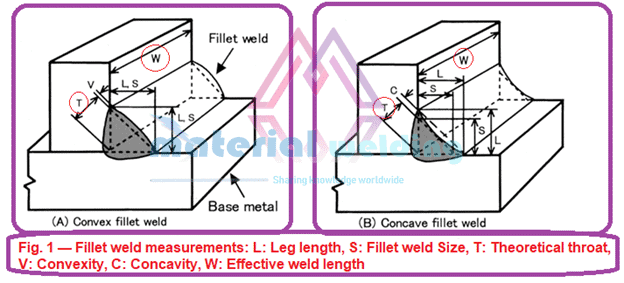

To determine the effective throat thickness, one needs to measure from the root of the joint to a point on or beyond its face where there is no undercut. The effective throat thickness can also be calculated using mathematical formulas based on variables such as leg size or throat size.

The basic formula for calculating the shear strength of a fillet weld is as follows:

- Shear Strength = 0.707 x Weld Throat x Weld Length x (Tensile Strength/3).

This formula takes into account three key factors that affect the strength of a fillet weld – its throat size, length and tensile strength.

By plugging in these values, engineers can determine whether or not the fillet weld is strong enough for its intended application.

Fillet Weld Shear Strength Calculation

Calculating the shear strength of a fillet weld involves determining the effective area of the weld and the allowable shear stress applied to the welded joint. The following formula is commonly used for this calculation:

Shear Strength = Weld Size × Weld Length × Allowable Shear Stress

Weld Size

The weld size, also known as the leg length, is the distance from the joint root to the outer edge of the weld. It’s essential to measure the weld size accurately, as it directly affects the shear strength of the weld. Weld size can be specified by the designer or determined using industry standards and guidelines. You can use fillet weld size formula to calculate the Fillet Weld size.

Weld Length

The weld length is the total length of the fillet weld along the joint. It’s important to note that the weld length may be different from the actual joint length, depending on the welding technique used and the required weld strength.

Allowable Shear Stress

The allowable shear stress is the maximum stress the weld can withstand without failure. It’s usually expressed in units of force per unit area, such as psi (pounds per square inch) or MPa (megapascals). The allowable shear stress depends on the filler material used, the design requirements, and applicable industry standards and codes.

Factors Influencing Fillet Weld Shear Strength

Several factors can influence the shear strength of a fillet weld, including:

- Weld size and geometry: As the weld size increases, the shear strength increases proportionally. However, it’s essential to maintain the correct weld geometry to ensure optimal strength.

- Filler material: The choice of filler material plays a crucial role in determining the weld’s shear strength, as different materials have varying allowable shear stresses.

- Welding technique: The quality of the weld and the consistency of the weld size and geometry depend on the welder’s skill and the welding technique used.

- Joint preparation: Proper joint preparation, including cleaning that ensure good weld fusion, can help ensure a strong and durable fillet weld.

Practical Examples

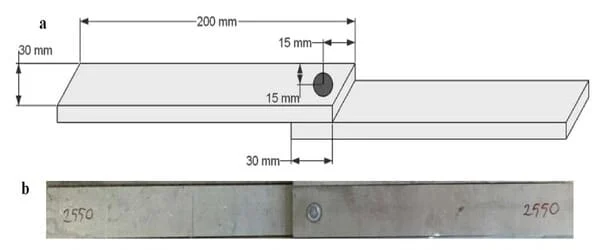

Let’s consider a practical example to illustrate the calculation of fillet weld shear strength. Suppose we have a fillet weld with a weld size of 0.25 inches and a length of 6 inches. The filler material used has an allowable shear stress of 20,000 psi.

– Shear Strength = Weld Size × Weld Length × Allowable Shear Stress

Shear Strength = 0.25 in × 6 in × 20,000 psi

Shear Strength = 30,000 lb

In this example, the fillet weld has a shear strength of 30,000 pounds.