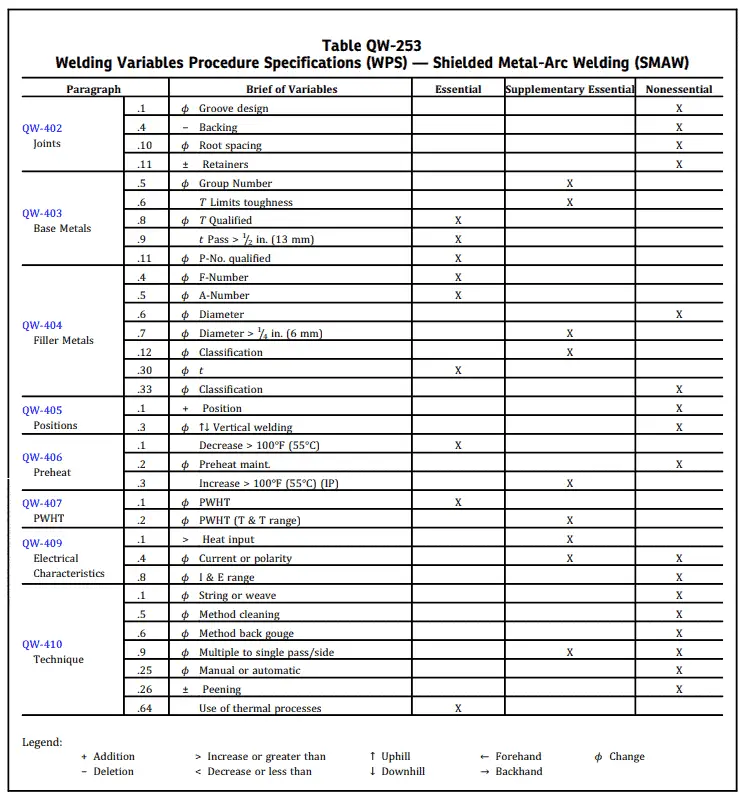

What must be done when a nonessential variable on a WPS is changed?

When a nonessential variable on a Welding Procedure Specification (WPS) is changed, it is necessary to revise the WPS to accurately reflect the modifications.

While requalification of the welding procedure is not typically required for nonessential variables, updating the WPS is essential for maintaining proper documentation and ensuring compliance with applicable standards.

“If non-essential variable changes, Revise your WPS and include the previous PQR number for accurate documentation.”

In simpler terms, if you have a Welding Procedure Specification (WPS) and need to use it for a different job but want to change some nonessential variables, you don’t have to re-qualify the WPS.

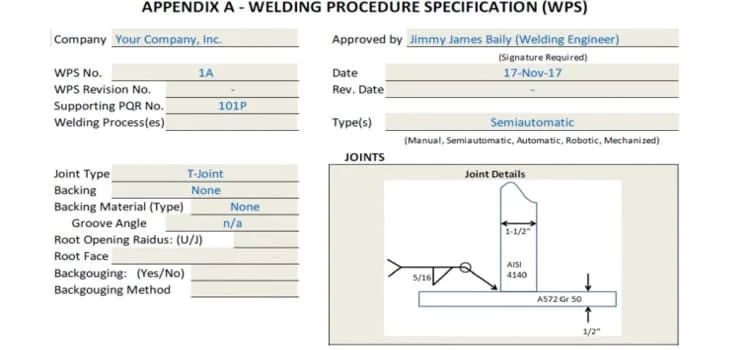

For instance, if you have a WPS for TIG Welding with a V groove joint design and want to use it for a job with a U groove joint design, you can revise the WPS by including the previous Procedure Qualification Record (PQR).

This change is considered nonessential and doesn’t require requalification or additional mechanical property tests since it doesn’t affect the welding’s mechanical properties.

Here are the steps to follow:

Identify the Nonessential Variable

Determine which nonessential variable(s) has been changed. Nonessential variables are those that can be modified without necessitating requalification of the welding procedure.

Document the Change

Clearly document the specific changes made to the nonessential variable(s) in the WPS. This includes updating any parameters or details that have been modified.

Revise the WPS

Update the WPS to reflect the changes accurately. This involves making the necessary modifications to the affected sections or tables within the document.

Maintain Documentation

Keep a record of the changes made to the WPS, including the date of revision and the reason for the modification. This documentation ensures traceability and provides a clear history of the WPS changes.

Communicate the Revised WPS

Distribute the revised WPS to the relevant stakeholders, including welding personnel, inspectors, and other individuals who require access to the updated information. Ensure that everyone involved is aware of the changes.

Follow Established Procedures

Adhere to any internal procedures or protocols related to WPS revisions. This may involve obtaining approval from a designated authority or following specific documentation control processes within your organization.

By revising the WPS to reflect the changes made to the nonessential variable(s), you maintain accurate and up-to-date documentation of the welding procedure. This promotes consistency, compliance, and clarity in the execution of welding activities.