What is welding slag?

Welding slag is a byproduct of welding processes that uses either directly flux (SAW or Electroslag welding) or flux coated rods such as stick welding or flux cored arc welding (FCAW).

Slag is generally made up of slag forming agents presents in the electrode coating that are burned off during the welding process and come out in liquid form when it cools down.

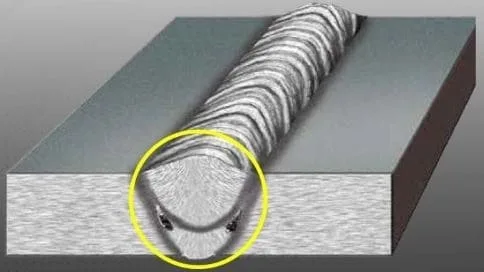

This liquid solidifies above the molten weld pool (slag become solid before weld start solidify), leaving behind a residue known as slag.

It usually has a greyish-black color, but other colors may occur depending on what type of flux forming agents present in the welding flux.

Slag in welding has a glassy appearance. Slag is created in Stick welding, FCAW, SAW, Electroslag welding, Electro gas welding and exothermic welding processes. Welding slag basically forms in all welding processes that uses welding flux or flux coated rods.

Welding slag varies depending on the type of metal that has been welded and can range in color from gray or black, to white or brown. Generally speaking, it tends to be abrasive and brittle with sharp edges.

Why Slag is formed in Welding?

Slag is a part of the welding bead that has to be removed after the weld is cool down, but many people are unfamiliar with what it is and why it forms in certain welding processes.

A slag is a layer of burned-off non-metal compounds from welding flux that forms over the welded joint during the welding process.

It serves several important functions such as protecting the molten weld metal from contamination and preventing the fast cooling of the weld.

The formation of slag begins after the burning of welding flux present in the electrode coating or the burning of external flux.

As heat is applied to the metals being joined, these materials melt and mix together to form a coating on top of the freshly formed molten weld pool that makes the weld bead.

This slag acts as an insulator between the molten metal below and the atmosphere above, reducing oxidation of the newly formed joint by preventing oxygen from entering into contact with it while still cooling down rapidly enough so that no further warping occurs due to overheating.

Welding Slag composition

The composition of welding slags includes silicates of iron, manganese and calcium, manganese and calcium titanates, aluminates, oxides, and other compounds.

Welding electrodes have different elements present in the coating or flux that forms the slag.

The main compositions of welding slag for stick welding are:

- Limestone,

- Calcium Fluoride (CaF2),

- Sodium silicate,

- Potassium silicate,

- Quartz,

- Lithium silicate,

- Iron Oxide (Fe2O3),

- Aluminum oxide (Al2O3),

- Zircon,

- Fluorspar,

- Mica,

- Silica,

- Titanium dioxide,

- Strontium carbonite.

- Magnesium Oxide (MgO)

- Silicon Dioxide (SiO2)

- Titanium Oxide (TiO2)

The slag compositions in submerged arc welding (SAW) are:

- Iron Oxide (Fe2O3),

- Aluminum oxide (Al2O3),

- Limestone,

- Calcium Fluoride (CaF2),

- Sodium silicate,

- Potassium silicate,

- Quartz,

- Calcium Oxide (CaO)

- Magnesium Oxide (MgO)

- Manganese Oxide (MnO)

- Silicon Dioxide (SiO2)

- Titanium Oxide (TiO2)

Functions of Slag in Welding?

The most important functions of slag, which are important for all types of fusion welding, include:

- ensuring the stability of the welding arc,

- Allow slow cooling of weld and thus help to maintain weld toughness and soft microstructure.

- Good formation of the welding seam profile,

- Protection of the welding pool from oxidation,

- Prevention of defects in the welding seams,

- Management of the chemical composition of the seam metal,

- Ensuring the required mechanical properties of the metal of the welding seam and the welded joint as a whole,

- Ensuring easy removal of the slag crust from the surface of the weld metal.

What is the purpose of the slag in welding?

The role of slag in welding and weld cladding is very important. Welding Slag works as a protective barrier over the weld while it cools down and solidifies, which helps to prevent any impurities from entering the joint. As well as acting as a shield during cooling.

Once cooled and hardened, slag can be easily removed either manually or with grinding tools such as a wire brush or angle grinder.

Its composition determines the arc characteristics, resistance against pore formation in the weld seams, volume, and ratio of harmful gases released during welding depend.

The stability of the electro slag process also depends on the slag. The interaction of molten slag with the metal of the welding pool significantly affects the chemical composition of the weld metal, on which, in turn, the structure and resistance against the formation of crystallization (hot) cracks and pores of the metal depend.

What causes welding slag?

Welding slag is a byproduct of the metal welding process that forms on top of the welded area. Slag is created while organic elements present in the welding flux are burned due to intense welding heat.

This flux converts to slag and produces a layer of material that prevents oxygen and other contaminants from penetrating into the welded area. Alloying elements which are added into the flux become part of the weld metal.

Slag can reduce electrical resistance along the welding arc, resulting in improved flow characteristics for molten metal as well as providing some thermal protection for base materials during welding operations.

Can you weld over slag?

Welding over slag is a concept that has been discussed for years in the welding industry. The question remains – can it be done and if so, what are the pros and cons? Welders must understand the risks involved before they attempt to weld over slag.

How to remove & clean welding slag?

Slag must be removed from a finished weld before it can be inspected and certified – this allows for better penetration, fusion, bead shape, and overall weld quality.

When welding, slag needs to be removed from the weld joint prior to continuing with the process.

This ensures that the weld will penetrate completely and produce a sound structure. However, if you opt to leave small amounts of slag on the weld, it will cause slag inclusion. Slag inclusion is a welding defect that requires weld repair.

Read more: Types of welding defects with their pictures.

Some stick welding rods creates very little to no slag. These rods coating is mainly made of cellulose compositions.

Example: E6010 and E6011 Rods. Below weld is made using E6010 rod and you can notice there is very little to no slag after welding as visible in below picture.

Is Welding Slag Magnetic?

When it comes to whether or not welding slag is magnetic, the answer is no.

Welding slag is the solidified material that remains on metal when welding. It consists of particles of non-metallic materials such as silicate, organic and non-organic materials.

Non-metals or these organic materials are not attracted to magnets so welding slag does not have any magnetic properties.

How to get rid of welding slag?

When working with welding, slag is a common problem. Slag is a layer of flux material that forms on the weld during the welding process. If left untreated, slag can interfere with the integrity of your welds and can cause slag inclusion.

One of the simplest methods for removing slag is by using a welder chipping hammer. This tool has a simple design consisting of two blades connected by a handle; one blade is used to chip away at the surface while pushing down on the other will help break up any large pieces remaining behind.

Another great option is using a grinder with knotted wire wheel attachment – this will grind down larger pieces into smaller particles that can then be swept away.

How hot is welding slag?

Welding slag is the by-product of welding and is typically composed of metal oxides and other materials. It is formed when the flux surrounding a welding arc melts, releasing smoke and vapor that solidify in contact with air.

This material can range in temperature from slightly warm to extremely hot depending on the application, so it’s important to know how to handle it safely.

Under normal circumstances, the welding slag temperature is around 300-500 degrees Celsius just after welding.

NEVER TOUCH WELDING SLAG WITH YOUR HAND EVEN IF IT SEEMS COLD AFTER WELDING.

Does MIG Welding produce Slag?

MIG welding is a commonly used welding process, but does it produce slag?

Slag is the hardened layer of residue left behind on the weld, which can affect the welding quality and require extra cleaning.

So, does MIG welding leaves slag?

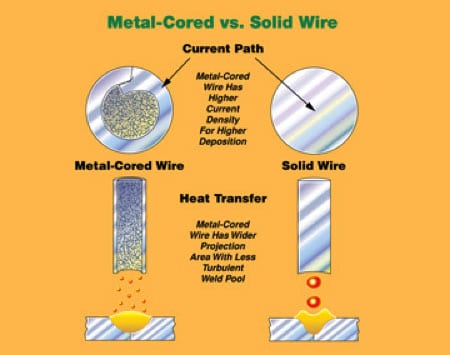

The answer is NO, as there is no flux used in MIG welding and welding wire is a solid wire rod used under gas shielding. There is no flux generation in MIG welding.

Read more: What is MIG Welding?

However, as the welding gas contains CO2, oxygen present in the carbon dioxide gas, reacts with silicon and manganese to make their oxides. These silicates you may notice in very small amounts on final welds. But remember, this is not SLAG.

Flux core arc welding (FCAW) uses a flux filler core wire, and in this process, slag is formed. FCAW Welding is also called gasless MIG sometimes but it is not actually MIG welding.

Does Welding Slag is hard to remove?

Welding slag can be difficult to remove, depending on the type of welding electrode and their coating types.

Rutile electrodes such as E6013 and E6012 rod slag removal is very easy. While welding slag produced by basic coating welding rods such as E7015 and E7018 are difficult to remove.

Also depending on the welding types also affect the slag removal. Submerged arc welding slag is usually gets removed automatically once it cools down. But in stick welding, you need to clean it manually in most cases.

The science behind is: liquid welding slag, if it contains significant amounts of oxides FeO, MnO, SiO2 or TiO2, oxidizes the surface of the hardened metal.

The resulting very thin oxide film is firmly held on the surface of the seam. If the surface of the metal is oxidized, and in the composition of the slag there are compounds that are firmly adhering to the oxide film (A12O3, Cr2O3, etc.), a strong retention of slag on the surface of the metal should be expected.

Compliance with the requirements for both easy slag severability and minimal oxidation of alloying elements is ensured by the use of slags with a low content of oxides FeO, MnO, SiO2 and TiO2, i.e. with reduced oxidative properties.

The separability of the slag crust from the seam surface also improves with an increase in the difference in the coefficients of thermal expansion of metal and slag.