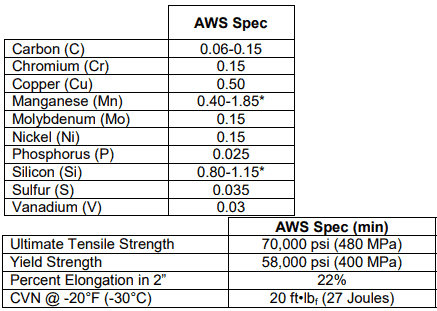

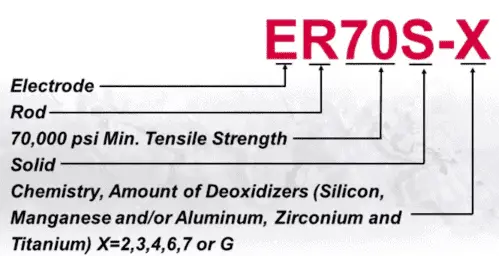

What is the difference between ER70S-2 (ER49S-2) and ER70S-3 (ER49S-2)?

ER70S-2 (ER49S-2) and ER70S-3 (ER49S-3) are both carbon steel solid filler wires used in TIG & MIG-MAG (GMAW) welding applications. The electrode specification for ER70S-2 & ER70S-3 is AWS A5.18, while the CSA equivalent of ER70S-2 & ER70S-3 is ER49S-2 & ER49S-3 respectively as per standard CSA W48-18..

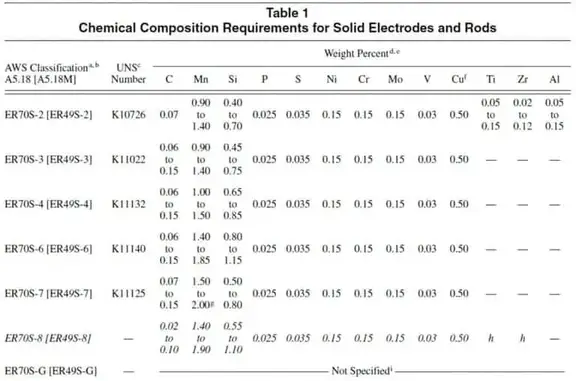

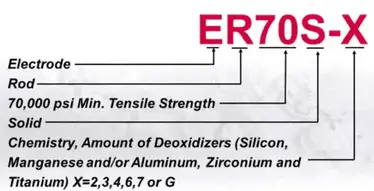

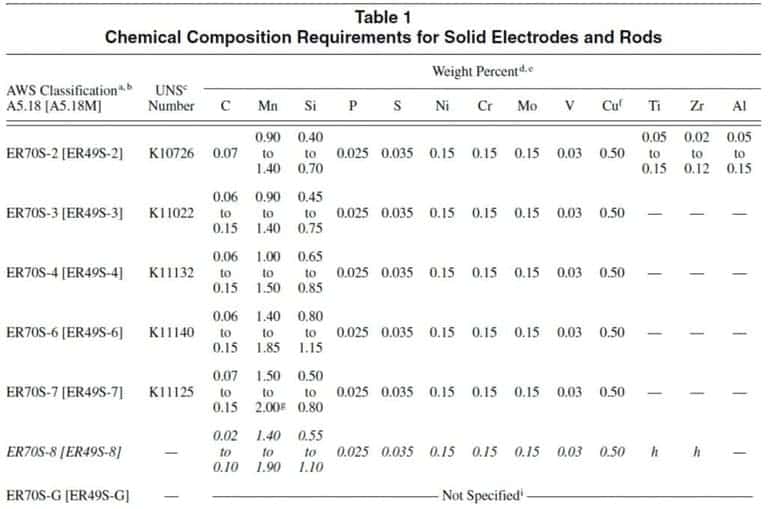

The chemical compositions for ER70S-2 (ER49S-2) and ER70S-3 (ER49S-2) are given in the below table for reference.

ER70S-2 (ER49S-2 or CSA-ISO 14341-B-G 49A 3 C1 S2) specification & features

ER70S-2 (ER49S-2) is a triple deoxidizer (zirconium, titanium, and aluminum) TIG-MIG Filler wire along with silicon and manganese.

Due to added deoxidizers, ER70S-2 is highly suitable for welding on semi-killed, rimmed steels, rusty materials, and in-field welding applications.

Most of these deoxidizers react with the oxides presents on the material surface and will not affects the weld metal properties due to their added alloying effects.

The weld deposit toughness of ER70S-2 (ER49S-2) is higher compared to ER70S-3 (ER49S-3) type filler wire/ rod.

They are used widely for welding root run & hot pass in piping jobs & for full piping joints welding of smaller diameters.

ER70S-6 welding wire MTC, specification, chemical-mechanical properties

ER70S-3 (ER49S-3 or B-G 49A 2 C1 S3)

ER70S-3 is also a solid wire conforming to AWS A5.18 or CSA-ISO 14341/ CSA W48 material specification.

The filler wire is used for TIG (GTAW) and MIG-MAG (GMAW) welding. Compared to ER70S-2, Er70S-3 does not have added deoxidizers such as aluminum, titanium, and zirconium.

The silicon and manganese present as the main alloying elements only works as deoxidizers purpose.

The equivalent of ER70S-3 as per CAN/CSA-ISO 14341:11 is B-G 49A 3 C1 S3. The chemical properties of ER70S-3 are given in the above table.

The amount of carbon is the same in both wires i.e. ER70S-2 & ER70S-3.

ER70S-2 (ER49S-2 or CSA-ISO 14341-B-G 49A 3 C1 S2) versus ER70S-3 (ER49S-3 or B-G 49A 2 C1 S3)

The major differences between ER70S-2 (ER49S-2 or CSA-ISO 14341-B-G 49A 3 C1 S2) vs.ER70S-3 (ER49S-3 or B-G 49A 2 C1 S3) are:

- ER70S-2 contains triple deoxidizer (zirconium, titanium, and aluminum) while ER70S-2 does not have any extra deoxidizer elements added.

- ER70S-2 is more suitable for weld-rimmed steel (Steel with more impurities) or on rusty surfaces or material with mill scale compared to ER70S-3 due to the higher amount of deoxidizers (aluminum, zirconium, titanium, manganese, and silicon) presents in the wire.

- Both ER70S-2 and ER70S-3 can be used for single-pass and multi-pass welds.

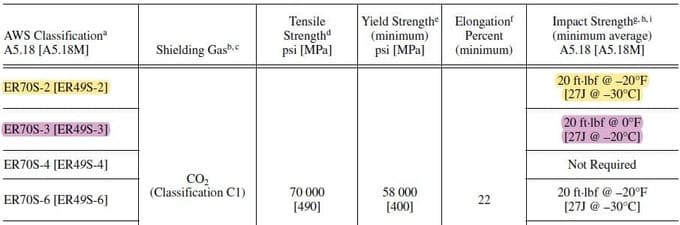

- ER70S-2 gives a higher weld metal toughness of 20 ft·lbf at a temperature of –20°F (27J at –30°C) while ER70S-3 gives a weld metal with minimum toughness of 20 ft·lbf at a temperature of –0°F (27J at –20°C).

- ER70S-3 should be used only with argon+CO2 gas mixture as welding using pure CO2 will reduce the amount of manganese present in the weldment and hence will reduce the strength of the weld metal. While ER70S-2 can be used in both pure CO2 and argon + CO2 mixture.

Any difference in the weld deposit strength of ER70S-6 & ER70S-3?

Honestly, both the wires meet the minimum specified mechanical tensile strength of 70 KSi (485 MPa) & yield strength of 58 KSi (400 MPa) but overall, ER70S-2 gives higher strength than ER70S-3 due to the lower loss of manganese during welding as deoxidizer.

As stated earlier, ER70S-2 gives higher weld metal toughness (Charpy impact) compared to ER70S-3.

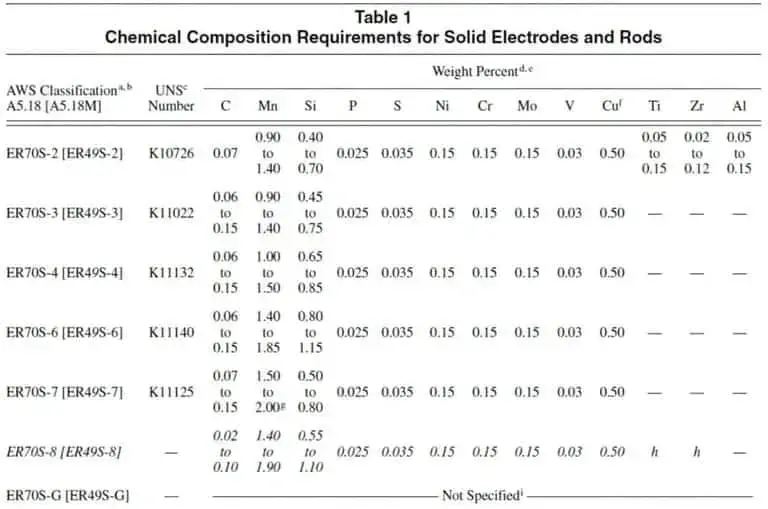

The toughness and mechanical properties such as tensile strength, yield strength, and elongation for ER70S-2 & ER70S-3 are given in the below table for reference.

Which shielding gases for ER70S-6 & ER70S-3?

What is the difference between ER70S-6 (ER49S-6) and ER70S-3 (ER49S-3)?

ER70S-2 can be used with pure CO2 and argon + CO2 mixture without any loss of mechanical properties of the weld.

However, ER70S-3 should be used with an argon + CO2 mixture only to have high weld strength.

The reason is- pure CO2 will consume some of the manganese presents in the wire due to an oxidation reaction that will take place between the oxygen released from CO2 dissociation and combination with manganese/ silicon to convert to manganese oxide or silicates.

Does change from ER70S-6 to ER70S-3 is allowed as per ASME Section IX for WPS-PQR?

Usually, when we choose a welding wire other than the qualified in the WPS requires the requalification of the PQR.

But under certain conditions, these changes are allowed. To understand this, we need to refer to the essential welding variables for the welding process in use as given in the ASME Section IX, Table QW-255 for GMAW, or QW-256 for GTAW- for example.

Here, related to the filler wire, change in F-Number, change in A-Number, change in filler product type are essential variables.

Now, both the wires have the same F-Number & A-Number & product form. but the classification is different i.e. ER70S-2 and ER70S-3. And the change in classification is a supplementary essential variable that is applicable if impact toughness is required.

This is the key clause, that tells that we need a new PQR/WPS qualification if we change from ER70S-2 to ER70S-3.

The reason, the toughness of ER70S-3 is 20 ft·lbf at 0°F (27J at –20°C) while ER70S-2 is 20 ft·lbf at -20°F (27J @ –30°C).

So, ER70S-3 is having lower impact toughness compared to ER70S-2 due to the toughness required temperature: –20°F (-30°C) vs –0°F (-20°C).

Hence, if the WPS is qualified with ER70S-2, you are not allowed to use it with ER70S-3.

But, if the WPS is with ER70S-3, you can use ER70S-2 without requalification as permitted in ASME Section IX.

The above statement is only applicable if the job requirements include weld toughness properties. I Hope, it makes sound now.