What is Bolt Strength Chart?

A bolt strength chart is an important tool for calculating the tension or clamp force that a bolted joint can withstand. It is used to select the correct size and type of bolt for specific applications, ensuring that the joint will be strong enough to handle any load it may incur.

The below bolt strength chart shows the amount of tension each type of bolt can reliably take before fatiguing or breaking under stress.

Commonly used Bolt Grades

The most commonly used bolt grades are:

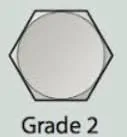

- Grade 2,

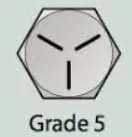

- Grade 5,

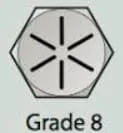

- Grade 8,

- Grade 307A,

- Grade A325,

- Grade 651.

US Bolts

| Marking on Bolt Head | Grade & Material |

Nominal Size (in inches) |

Mechanical Properties | ||

|---|---|---|---|---|---|

| Proof Load (Ksi) |

Minimum Yield Strength (Ksi) |

Minimum Tensile Strength (Ksi) |

|||

|

307ALow carbon steel |

1/4″ to 4″ | N.A. | N.A. | 60 |

without Markings |

Grade- 2Low/ medium carbon steel |

1/4″ to 3/4″ | 55 | 57 | 74 |

| Over 3/4″ to 1.5″ | 33 | 36 | 60 | ||

3 visible Radial Lines |

Grade 5Medium carbon steel, quenched & tempered |

1/4″ to 1″ | 85 | 92 | 120 |

| Over 1″ to 1.5″ | 74 | 81 | 105 | ||

6 visible Radial Lines |

Grade 8Medium carbon alloy steel, quenched & tempered |

1/4″ to 1.5″ | 120 | 130 | 150 |

|

Grade A325Carbon or alloy steel with or without boron |

1/2″ to 1.5″ | 85 | 92 | 120 |

| Markings on stainless steel Vary |

18-8 (304) & 316 StainlessSteel alloy with chromium and nickel |

All sizes thru 1″ | N/A | minimum 20 but 65 Typical | minimum 65 but 100 – 150 Typical |

|

651 Silicon bronzesilicon bronze bolt |

1/4″ to 3/4″ | N.A. | 55 | 70 |

| 7/8″ to 1.5″ | N.A. | 40 | 55 | ||

|

Aluminum Grade 2024Aluminum bolt |

All sizes | N.A. | 36 | 55 |

Metric Bolts |

|||||

| Marking on bolt head | Bolt grade & Material |

Nominal bolt Size (mm) |

Mechanical Properties | ||

| Proof Load (N/mm2) |

Minimum Yield Strength (N/mm2) |

Minimum Tensile Strength (N/mm2) |

|||

|

8.8 ClassQ &T Medium carbon steel |

Almaximum 16 mm | 575 |

650 |

800 |

| 16 to 72 mm | 600 | 650 | 830 | ||

|

10.9 ClassQ & T ( quenched & tempered) |

5mm – 100mm | 830 |

940 |

1040 |

|

12.9 ClassQ & T ( quenched & tempered) Alloy steel, |

1.6 to 100 mm | 970 |

1100 |

1220 |

| generally marked A-4 or A-2 |

A-2 & A-4 Stainlessstainless steel |

sizes up to 20 mm | N/A |

minimum 210 |

minium 500 |