What is a Prequalified Welding Procedure Specification?

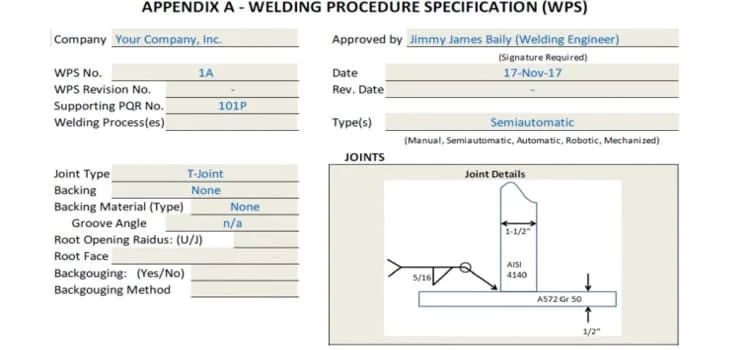

Prequalified welding procedure specifications (WPSs) are welding procedures that have been assessed by the AWS D1 Committee and have demonstrated satisfactory performance.

As a result, they do not require the same level of qualification testing as other welding procedures. However, it’s important to note that prequalified WPSs still need to be documented in writing.

Additionally, it’s necessary to ensure that welders are properly qualified even when using prequalified Welding Procedure Specifications. The benefit of using a prequalified welding procedure specification is that it can save time and money in the welding process.

The prequalification process eliminates the need for additional testing, which can be time-consuming and expensive. Additionally, prequalified welding procedures are generally accepted by most code organizations, which can reduce the need for multiple qualifications for different projects.

Limitations of a Prequalified Welding Procedure Specification-WPS

Welding procedures that have been qualified by test are not subject to the same restrictions and limitations as prequalified welding procedures. Prequalified welding procedures must adhere to all prequalified requirements outlined in the welding code.

If a prequalified condition is not met, the welding procedure cannot be considered prequalified. It’s essential to ensure that all prequalified conditions are met to take advantage of prequalified welding procedures.

Here are some limitations of a Prequalified Welding Procedure Specification (WPS):

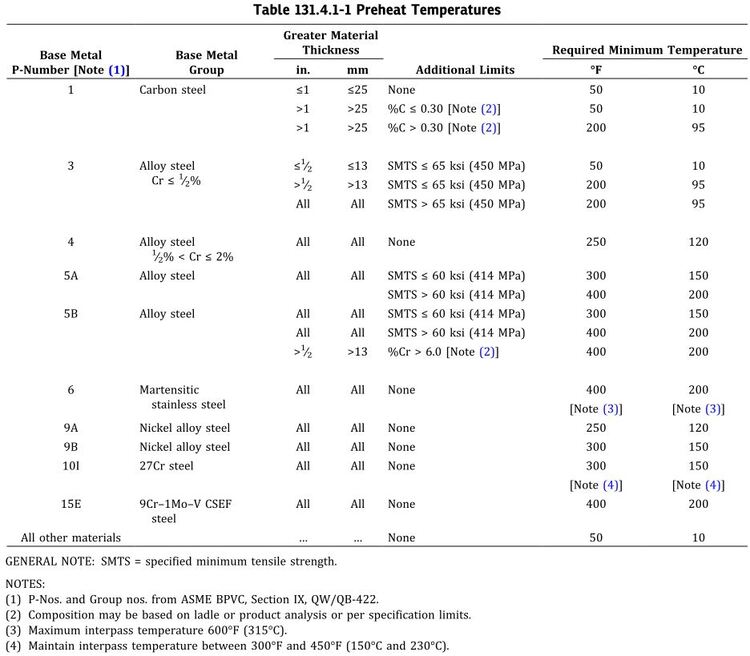

- Prequalified WPSs have limitations on the material thickness and joint type for which they can be used. If the project requirements exceed these limitations, a qualified WPS may be necessary.

- Prequalified WPSs may not address specific material or welding requirements for a particular project. In such cases, a qualified WPS may be required to ensure that the project-specific requirements are met.

- Prequalified WPSs do not account for changes in the base material or welding process that may affect the quality of the weld. If such changes occur, a qualified WPS may be necessary.

- Prequalified WPSs do not address non-standard welding procedures or techniques, which may be required for certain projects. In these cases, a qualified WPS may be necessary.

- Prequalified WPSs still require that welders be appropriately qualified and trained to ensure that the welding process meets the project requirements.

References: