ASME Section IX is a standard developed by the American Society of Mechanical Engineers (ASME) that outlines the requirements for welding and brazing procedures, as well as the qualification of welders, brazers, and welding and brazing operators.

It is a critical resource for professionals involved in the fabrication and inspection of pressure vessels, pipelines, and other welded and brazed structures. In this article, I have covered a complete overview of ASME Section IX, its purpose, and its key features.

Purpose of ASME Section IX

ASME Section IX is a standard developed to ensure that welding and brazing procedures are carried out safely and consistently. It provides guidelines for the design, fabrication, inspection, and testing of welded and brazed structures, as well as the qualification of personnel involved in these processes.

The standard is widely used in a range of industries, including oil and gas, petrochemical, aerospace, and nuclear power. Compliance with ASME Section IX is often a requirement for certification and regulatory compliance.

Parts of ASME Section IX

ASME Section IX of the Boiler and Pressure Vessel Code provides the requirements for qualification of welding and brazing procedures, welders, brazers, and welding and brazing operators.

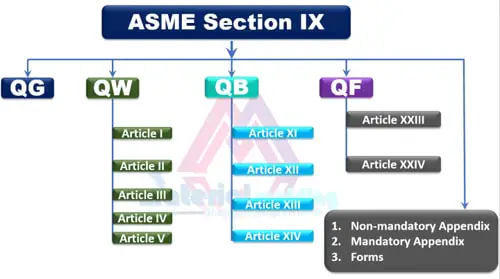

The organizational and structural parts of ASME Section IX are as follows:

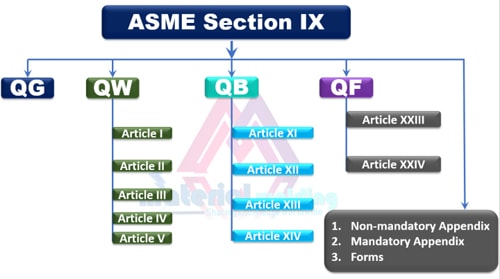

ASME Section IX Code is divided into four different sections as follow:

- Part QG contains general requirements for all material-joining processes.

- Part QW contains requirements for welding.

- Part QB contains requirements for brazing.

- Part QF contains requirements for plastic fusing.

Part QW- Welding is further divided into 5 articles:

- Article: i- Welding General Requirements.

- Article: ii- Welding Procedure Qualifications.

- Article: iii- Welding Performance Qualifcation.

- Article: iv- Welding Data.

- Article: v- Standard Welding Procedure Specifications (SWPSS).

Part-QB: Brazing is divided into 4-Parts as follow:

- Article xi: Brazing General Requirements.

- Article xii: Brazing Procedure Qualifications.

- Article xiii: Brazing Performance Qualifications.

- Article xiv: Brazing Data.

Part-QF: Plastic Fusing is divided into:

- Article xxi: Plastic Fusing General Requirements.

- Article xxiii: Plastic Fusing Performance qualifications.

- Article xxiv: Plastic Fusing Data.

In addition to above, ASME Section IX, contains Mandatory and non-mandator appendix that are useful aids to procedure and performance qualifications.

Following are the Appendix added to the ASME Section IX:

- Nonmandatory Appendix B: Welding and Brazing Forms.

- Nonmandatory Appendix D: P-Number Listing.

- Mandatory Appendix E: Permitted SWPSS Listing.

- Mandatory Appendix F: Standard units for use in equations.

- Nonmandatory Appendix G: Guidance for use of U.S> customary and S.I. units the ASME Codes.

- Nonmandatory Appendix H: Waveform controlled welding.

- Mandatory Appendix J: Guideline for requesting P-Number assignments for base metal not listed in Table QW/QB-422.

- Nonmandatory Appendix K: Guidance on invoking section ix requirements in other Codes, standards, specifications, and contract Documents.

- Nonmandatory Appendix L:

- Welders and welding operators qualified under ISO 9606-1:2012 and iISO 14732-2013.

General Requirements:

This section provides an overview of the scope, applicability, and definitions of terms used in the document. It outlines the minimum requirements for welding, brazing, and their associated personnel qualification.

Welding and Brazing Procedure Qualification:

This section outlines the procedures for qualifying welding and brazing procedures, including the necessary documentation, test specimens, and acceptance criteria.

Welder and Welding Operator Qualification:

This section outlines the requirements for qualifying welders and welding operators, including the necessary documentation, test specimens, and acceptance criteria.

Brazer and Brazing Operator Qualification:

This section outlines the requirements for qualifying brazing filler metals and brazing operators, including the necessary documentation, test specimens, and acceptance criteria.

Overall, ASME Section IX is a comprehensive document that provides a standardized approach to welding and brazing qualification. It helps ensure that these processes are performed safely and efficiently, and that qualified personnel are involved in the process.

Key Features of ASME Section IX

The standard covers a range of topics related to welding and brazing, including:

Welding and brazing procedure qualification:

ASME Section IX outlines the requirements for qualifying welding and brazing procedures, including the materials, equipment, and techniques used in the process. It also defines the criteria for evaluating the quality of welded and brazed joints required for welder/ operator (performance) and procedure qualification.

Welder and brazer qualification:

The standard also specifies the requirements for qualifying welders and brazers, including the minimum level of experience and skill required to perform the work. It also outlines the process for re-qualifying welders and brazers, as well as the requirements for maintaining their certification.

Welding and brazing documentation:

ASME Section IX requires that all welding and brazing procedures be documented and maintained for future reference. This includes records of the materials used, the equipment and techniques employed, and the results of any tests performed.

Inspection and testing:

The standard also specifies the requirements for inspecting and testing welded and brazed welding test coupons for procedure and performance qualifications, including the use of non-destructive testing (NDT) techniques such as radiography, ultrasonic testing, and dye penetrant inspection as well destructive testing using:

- Tensile Testing.

- Bend Testing.

- Hardness.

Benefits of ASME Section IX

Compliance with ASME Section IX offers a range of benefits, including:

Improved safety: By providing guidelines for safe welding and brazing practices, ASME Section IX helps to ensure that structures are fabricated and maintained in a safe and reliable manner.

Consistent quality: The standard provides a framework for consistent welding and brazing practices, which can help to reduce variability and improve the quality of the final product.

Regulatory compliance: Compliance with ASME Section IX is often required for certification and regulatory compliance, particularly in industries such as oil and gas, petrochemicals, and nuclear power.

Conclusion

ASME Section IX is a critical resource for professionals involved in the fabrication and inspection of welded and brazed structures. By providing guidelines for safe and consistent welding and brazing practices, the standard helps to ensure the safety and reliability of these structures, as well as compliance with regulatory requirements.