Deposition Rate in Welding

Welding is a critical manufacturing process used across a wide range of industries, from automotive and aerospace to construction and infrastructure.

One of the most important aspects of welding is the amount of welding wire that is melted and deposited onto the workpiece, known as the deposition rate.

A high deposition rate can help reduce welding time and increase productivity, while a low deposition rate can lead to welding defects and an overall reduction in efficiency.

Therefore, understanding the factors that affect welding wire deposition rates is crucial for achieving high-quality welds and optimizing welding performance.

In this article, we will provide an overview of welding wire deposition rates, the factors that influence them, and some general guidelines for typical deposition rates for common welding processes.

Factors Influencing the Welding wire Deposition rate

There are several factors that influence the welding wire deposition rate, including:

Welding process

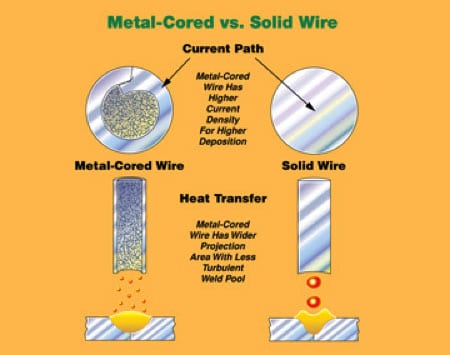

Different welding processes have different deposition rates. For example, gas metal arc welding (GMAW) typically has a higher deposition rate than gas tungsten arc welding (GTAW).

Wire diameter

The diameter of the welding wire can affect the deposition rate. Generally, a larger wire diameter will result in a higher deposition rate, but it may also require higher amperages and welding currents.

Welding current

The welding current is a critical factor that affects the deposition rate. Higher welding currents typically result in higher deposition rates, but they can also increase the risk of welding defects such as porosity and undercut.

Welding speed

The welding speed is another important factor that affects the deposition rate. A higher welding speed can increase the deposition rate, but it may also lead to a decrease in weld penetration and quality.

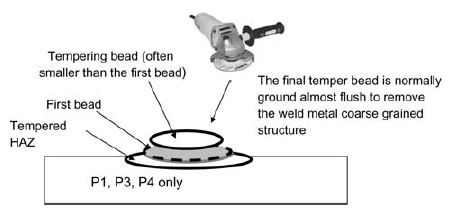

Joint design

The joint design, including the type of joint and the gap between the workpieces, can affect the deposition rate.

A joint with a larger gap may require a higher deposition rate to fill the gap, but it can also increase the risk of welding defects.

Shielding gas

The type and flow rate of the shielding gas can affect the deposition rate. A higher flow rate of shielding gas can improve arc stability and reduce the risk of porosity, which can lead to a higher deposition rate.

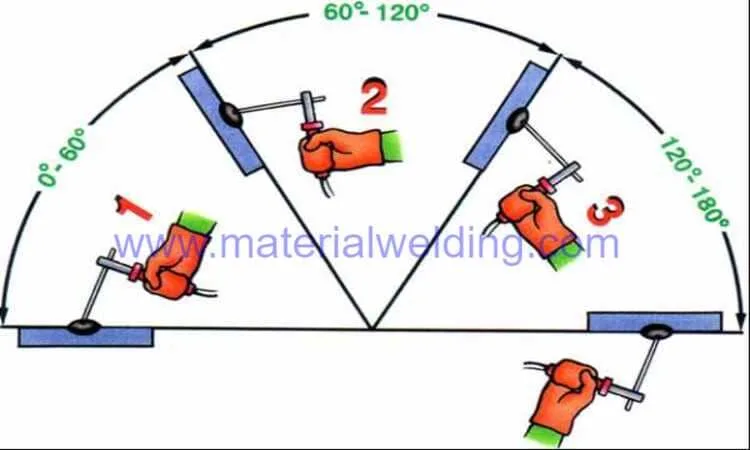

Welding position

The welding position, whether it is flat, horizontal, vertical, or overhead, can also affect the deposition rate.

Some welding positions may be more challenging than others, which can affect the welding speed and overall deposition rate.

What is Welding wire deposition rates?

Welding wire deposition rate refers to the amount of welding wire that is melted and deposited onto the workpiece per unit time.

The deposition rate is affected by several factors, including the welding process used, the wire diameter, the welding current, and the welding speed.

Welding wire deposition rates for common welding processes

Gas metal arc welding (GMAW)

GMAW, also known as MIG welding, is a popular welding process used in many industries.

The deposition rate for GMAW can vary depending on the wire diameter and the welding current.

Generally, a 0.035-inch diameter wire can deposit 10-16 pounds of metal per hour, while a 0.045-inch diameter wire can deposit 16-27 pounds of metal per hour.

Flux-cored arc welding (FCAW)

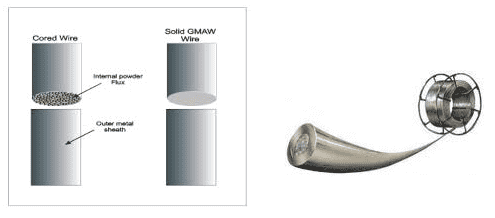

FCAW is similar to GMAW, but uses a tubular wire filled with flux instead of a solid wire.

The deposition rate for FCAW can vary depending on the wire diameter, the welding current, and the type of flux used. Generally, a 0.045-inch diameter wire can deposit 10-20 pounds of metal per hour.

Gas tungsten arc welding (GTAW)

GTAW, also known as TIG welding, is a precise and versatile welding process commonly used for thin materials.

The deposition rate for GTAW is generally lower than GMAW and FCAW, with a typical range of 2-5 pounds of metal per hour.

Submerged arc welding (SAW)

Submerged arc welding (SAW) is a welding process that utilizes a continuous wire electrode, a flux powder, and a blanket of granular flux to shield the welding area.

The wire electrode is submerged in the flux, which melts and provides protection to the weld pool.

The deposition rate for SAW can vary depending on the wire diameter, the welding current, the welding speed, and the joint design.

Typically, SAW has a high deposition rate due to its ability to weld with high amperages and long weld runs.

Here are some general guidelines for typical SAW deposition rates:

- Single-wire SAW: A 3/32-inch diameter wire can deposit 8-12 pounds of metal per hour, while a 5/32-inch diameter wire can deposit 25-30 pounds of metal per hour.

- Twin-wire SAW: A twin-wire SAW setup can deposit up to twice the amount of metal as a single-wire setup. With a 5/32-inch diameter wire, twin-wire SAW can deposit up to 60 pounds of metal per hour.

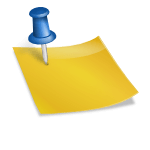

Welding wire deposition rates Calculation

Read more: How to Calculate Deposition Rate per hour in Welding: Comprehensive Guide

Calculating the welding wire deposition rate requires some basic information about the welding process and the welding wire being used. Here are the steps to calculate the welding wire deposition rate:

- Determine the cross-sectional area of the welding wire. This can be calculated by squaring the wire diameter and multiplying by π/4. For example, the cross-sectional area of a 0.045-inch diameter wire is (0.0452 x π) / 4 = 0.0016 square inches.

- Determine the welding speed. This is the speed at which the welder moves the welding gun along the joint.

- Determine the length of the weld bead. This is the length of the joint that is being welded.

- Determine the welding time. This is the time it takes to weld the length of the weld bead.

- Calculate the deposition rate by multiplying the cross-sectional area of the welding wire by the welding speed and the welding time.

- For example, if a welder is using a 0.045-inch diameter wire, welding at a speed of 10 inches per minute, and welding a 10-inch long bead, and the weld time is 5 minutes, the calculation would be as follows:

Deposition rate = (0.0016 square inches x 10 inches/minute x 5 minutes) = 0.08 cubic inches per minute

This means that the welder is depositing 0.08 cubic inches of metal per minute using this welding setup.

By adjusting the welding speed, welding current, and other factors that influence deposition rate, a welder can optimize their welding process and achieve the desired deposition rate for their application.