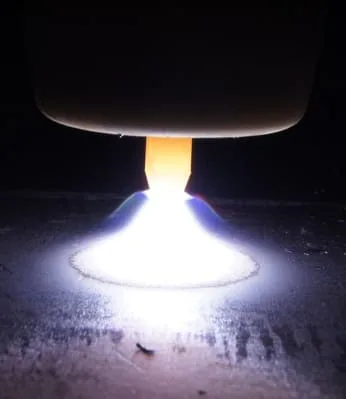

How hot is a Welding Arc?

Arc welding is one of the oldest and most popular welding processes used in manufacturing and construction today. But how hot does an arc welder get?

The heat generated by an arc welder during the welding process can vary greatly from one type of welding to another. Generally speaking, short-circuiting arc welders will generate lower temperatures than spray transfer welders.

However, all types of arc welders will produce enough heat to create a molten pool at the joint where the two pieces are being joined together.

This molten pool can reach temperatures up to 6500 degrees Fahrenheit depending on which type of electrode is being used and what kind of material is being fused together.

What affects the arc welder temperature?

The temperature of this electric arc varies depending on the type of welders being used and their settings – such as amperage or voltage – so it’s important for welders to understand how these settings affect the temperature and strength of their finished welds.

Type of welding process, welding gas, welding parameters (Amperage & voltage) – All of these influence the welding arc temperature.

How hot is an arc welder?

Arc welders produce a temperature of up to 8,000 degrees Fahrenheit when in use. This is more than enough heat to melt most metals and alloys quickly and easily.

In addition to the extreme heat generated by arc welding, the machine also produces blinding light that can cause damage to eyesight if not properly protected.

For this reason, it is highly recommended that safety goggles are always worn while arc welding is taking place.

Furthermore, prolonged exposure to arc welders can cause burns on skin due to their immense temperature output.

To avoid this danger, protective clothing made of fire-resistant material should be worn at all times while welding.

Welding Arc Temperature in different welding processes

Welding is a common technique used to join materials together. It involves the use of extreme temperatures to fuse metals and other materials.

The temperature created during welding is known as the arc temperature and it varies depending on the type of welding process being used.

Below are the temperature listed for different welding arc types:

- Gas Welding, Acetylene Flame: 5500°F (3038°C),

- Stick Welding (SMAW): 3200°F (1760°C),

- TIG Welding: 3400-4500°F (1871-2482°C),

- MIG Welding: 5000- 6,000°F (2800- 3315°C),

- FCAW Welding: 5000- 6,000°F (2800- 3315°C),

- SAW Welding: 10000°F (5726°C),

- Plasma Arc Welding: 16 600°C (30,000°F),

- Laser Welding: >17000°F (9500°C)

- Electroslag Welding: 1925°C (3500°F)

- Brazing: >840°F (450°C),

- Friction Stir Welding: 840°F to 900°F (450°C to 500°C)

How Hot is MIG Welding?

Arc temperatures are highest in MIG Welding (gas metal arc welding processes) and can reach up to 6500°F (3600°C). This is significantly higher than Stick Arc Welding which produces an arc temperature of approximately 3200°F (1760°C).

How Hot is TIG Welding?

Furthermore, Tungsten Inert Gas Welding produces an even lower arc temperature, at around 3400-4500°F (1871-2482°C).

Welding Heat

Heat plays a key role in welding as it affects both the properties of the welded joint and how well it holds up over time.

It is therefore essential to understand how welding heat, temperature, and other factors interact to ensure that welds are strong, durable, and able to withstand any stress or strain they may encounter.

One of the most important factors affecting welding arc heat is amperage. Higher levels of amperage mean more current can flow through the electrodes which increases heat generation during welding.

Also important are electrode size, polarity, travel speed, and voltage; all affect how much heat is generated during welding which then affects weld penetration into base material as well as bead shape formation.

Reference: