What is CFW in Construction?

CFW, which stands for continuous fillet weld, is an instruction given to the fabricator or boilermaker, indicating the need for a fillet weld joint to connect two steel pieces. The objective of this weld is to create a continuous, uninterrupted fillet weld.

“CFW- Continuous Fillet Weld“

Continuous fillet welds are employed to ensure that there are no visible starting or stopping points in the weld.

Additionally, they are used to fully seal the interior of hollow steel components, such as CHS (Circular Hollow Sections).

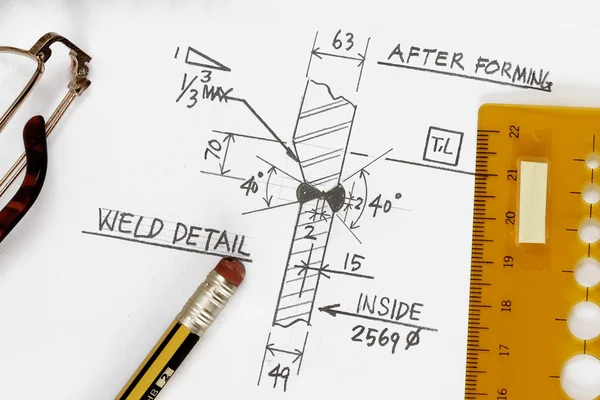

A common specification for a continuous fillet weld is denoted as 6CFW or 8CFW, where the number represents the leg length of the weld.

The specific leg length is determined by the structural engineer based on factors such as the loads on the weld and the strength of the parent metals.

CFW meaning in Welding

In welding, CFW stands for Continuous Fillet Weld. It is a type of weld joint where a fillet weld is made continuously along the length of the joint, without any interruptions or stops.

The continuous fillet weld provides a strong and consistent connection between two pieces of metal. It is commonly used in structural welding applications to join components together, ensuring structural integrity and load-bearing capacity.

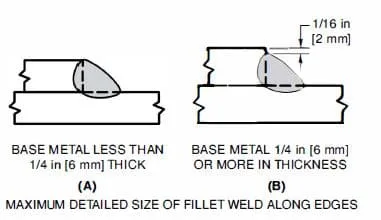

The size and dimensions of the continuous fillet weld are determined based on engineering and design specifications, considering factors such as the material thickness, joint configuration, and expected loads.

If a Welding Symbol on drawing says 6mm CFW UNO it’s mean a 6mm continuous fillet weld unless noted otherwise to be welded at the arrow location.