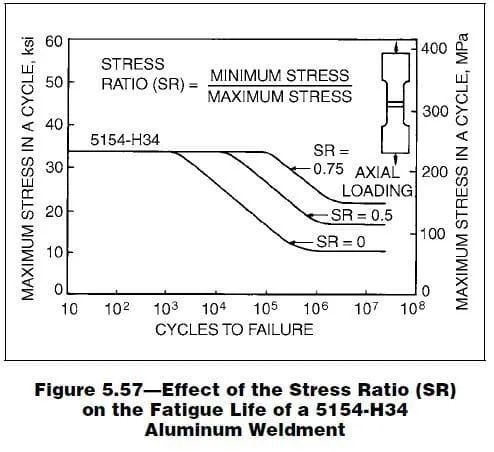

What is fatigue stress ratio?

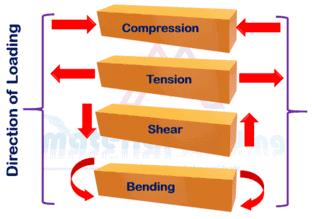

Fatigue stress ratio is a term that refers to the level of fatigue experienced by an object under stress. This concept is particularly important in engineering (material science & design), where materials and structures need to withstand repeated cycles of stress without breaking down.

It is used to determine the level of cyclic loading that a material can withstand without experiencing fatigue failure. In simple terms, it compares the maximum stress experienced by a material during one cycle of loading to the minimum stress experienced during the same cycle.

The fatigue stress ratio is calculated by dividing the minimum stress required to cause failure in a material by the maximum stress it can withstand.

The fatigue stress ratio is an important factor to consider when designing structures or components that will be subjected to cyclic loading. If the ratio is too high, it means that the material will quickly wear out and fail due to repeated stresses. Engineers must therefore aim for a low fatigue stress ratio when designing machinery or other equipment that will be subject to frequent use.

Fatigue stress ratio Formula

The Fatigue Stress Ratio Formula is a critical tool used to determine the fatigue life of a material. It is a mathematical formula that helps predict how long a material will last under repeated stress cycles. The formula takes into account the maximum stress level and the minimum stress level that an object experiences during its lifetime.

The formula for calculating fatigue stress ratio is simple:

R = S_min / S_max.

Where,

- R = fatigue stress ratio

- S_min = minimum fatigue stress

- S_max = maximum fatigue stress

A high value of R indicates that there is less fluctuation between maximum and minimum stresses, which means that the component will be able to withstand more cycles before failure occurs.

Fatigue stress ratio calculation examples

To start, let’s consider a simple example where we have a shaft that is subjected to cyclic bending loads.

For instance, consider a shaft made of AISI 1045 steel subjected to a rotating bending load. The maximum cyclic stress on the shaft is 50 ksi, while the endurance limit of AISI 1045 steel is 30 ksi.

Using these values, we can calculate the fatigue stress ratio as follows:

- Fatigue Stress Ratio (FSR) = Minimum Cyclic Stress / Maximum cyclic stress = 30 /50 =0.6.