What is an AC Welder?

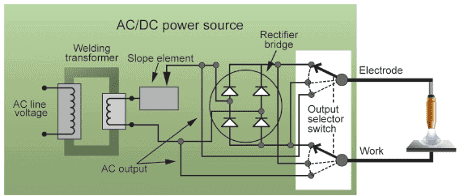

An AC welder is a type of welding machine that uses alternating current (AC) to generate the electric arc needed to weld metal materials together. like a DC welder, there is not rectifying circuit present in an AC Welder to convert AC to DC.

The AC welder works by sending an electric current through a welding electrode, which is in contact with the metal being welded. This creates a high temperature arc that melts the metal and fuses it together.

What is AC Welder used for?

AC welders are commonly used for welding materials like aluminum and magnesium, which require a higher frequency of polarity changes to maintain a stable arc. AC welders are also used for welding in situations where there is a need for deeper penetration and a higher level of heat input.

AC welders can be used for a variety of welding techniques including TIG (tungsten inert gas) welding, stick welding, and MIG (metal inert gas) welding. They are generally more versatile than DC welders, which only use direct current.

Where we can use AC Welder?

AC is not suitable for certain types of electrodes and for welding certain metals. So before deciding to go in for an AC power source, one must make sure that the electrodes he is going to use and the metals he is going to weld are suitable for AC.

The electrode producer indicates the suitability of each electrode type for AC or DC on the carton and the descriptive leaflet. He also indicates the current range for each size of electrode. This data should be studied before deciding to buy a power source.

To make a choice between AC and DC, the following points must be considered:

- All types of electrodes work on DC while some non-ferrous types and basic low-hydrogen ferritic type electrodes may not give a stable arc with AC. In AC welding, because of the reversing nature of the current, flux coatings must contain enough arc stabilizers to re-ignite the arc immediately after the current comes to zero during each cycle.

- When using small-diameter electrodes at low amperages, DC has a definite advantage over AC, both for starting and maintaining the arc.

- For all electrode sizes, maintaining a short arc is easier with DC than with AC, except when iron-powder electrodes are used.

- Vertical and overhead welding on thick sections is easier with DC than with AC, because a stable arc can be maintained at lower currents.

- Effect of polarity: DC has the advantage of two polarities, which means that the electrode can be made negative or positive. Straight polarity (i.e. electrode negative) can be used for MMAW of all steels (except when low-hydrogen electrodes are used), but not for most non-ferrous metals. With straight polarity, more of the arc heat is concentrated on the electrode and consequently melting and deposition rates are higher, welding is more rapid and the workpiece is less susceptible to distortion. Higher welding speed is possible. However, penetration is shallower and narrower.

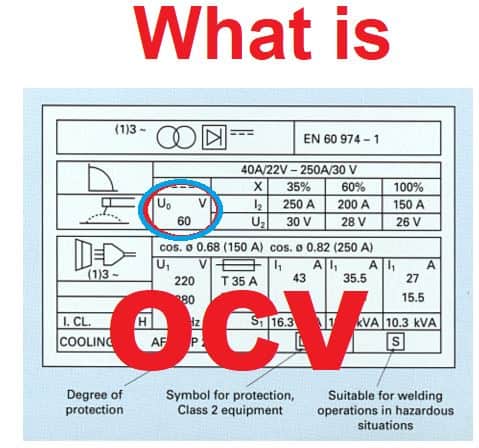

Welding Polarity in AC Welding

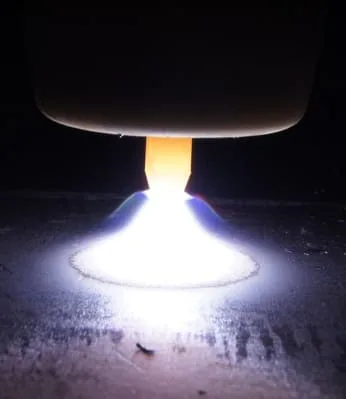

In AC welding, a choice of polarity is non-existent because AC combines reverse and straight polarity in regular cycles. Hence AC gives penetration and electrode melting rate intermediate between those given by DC + and DC-.

Reverse polarity (i.e., electrode positive) is used with basic low-hydrogen electrodes and for most non-ferrous metals. It produces maximum penetration for a given set of conditions.

This characteristic makes reverse polarity the better choice for root passes in groove welds made with use of backing bars, and for vertical and overhead welding.

AC Welding and Arc blow

DC can cause the problem of arc blow, especially when welding is done in corners, near the ends of joints or on structures involving several pieces coming together. Welding with high currents on heavy structures may also give rise to arc blow, more so when the fit-up is bad. AC does not present this problem.

Pros and cons of ac vs dc welding

AC welding and DC welding both have their advantages and disadvantages, and the choice between them depends on the specific application and the type of metal being welded.

Related reading: DC vs AC Welding

Pros of AC Welding:

- AC welding is better suited for welding aluminum and other non-ferrous metals because it prevents oxide build-up, which can weaken the weld.

- AC welding produces a stable arc that is less likely to stick, making it easier to use for beginners.

- AC welding provides deeper penetration than DC welding, making it better suited for thicker metals.

Cons of AC Welding:

- AC welding produces a less precise weld than DC welding, which can be an issue for certain applications.

- AC welding requires a higher amperage and produces more heat, which can be a problem when welding thin or delicate materials.

- AC welding can produce a noisy and unstable arc, which can make it difficult to use in certain conditions.

Pros of DC Welding:

- DC welding produces a more stable and precise weld, making it better suited for applications where accuracy is critical.

- DC welding can be used for a wider range of materials, including ferrous and non-ferrous metals, and can be used to weld thinner materials.

- DC welding is more efficient than AC welding, as it requires less amperage to produce the same amount of heat.

Cons of DC Welding:

- DC welding can cause oxide build-up on non-ferrous metals, which can weaken the weld.

- DC welding can produce a more difficult-to-control arc, which may be challenging for beginners.

- DC welding provides less deep penetration than AC welding, making it less suitable for thicker metals.