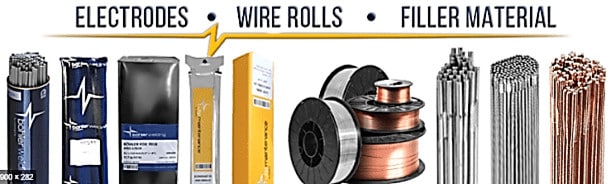

Filler metals play a crucial role in welding, as they are used to join two or more metal components together. The American Welding Society (AWS) has established a classification system to categorize and standardize filler metals based on their chemical composition, mechanical properties, and intended applications.

In this article, we will explore the AWS classifications of filler metals and understand how they help ensure proper selection and usage for various welding processes.

Understanding AWS Classification System

The AWS classification system provides a standardized method for identifying and selecting filler metals based on specific criteria. Each classification consists of a series of letters and numbers that convey important information about the filler metal’s characteristics. Let’s break down the key components of the AWS classification system:

The AWS classification system provides a standardized method for identifying and selecting filler metals based on specific criteria. Each classification consists of a series of letters and numbers that convey important information about the filler metal’s characteristics. Let’s break down the key components of the AWS classification system:

- Prefix: The prefix indicates the type of filler metal. For example, “E” is used for electrodes, “ER” for solid wires, “T” for tubular wires, and “R” for rods.

- First & Second Digit: The first digit indicates the minimum tensile strength of the deposited weld metal. It represents the approximate value in thousands of pounds per square inch (ksi).

- Third Digit: The third digit irepresents the welding position(s) in which the filler metal can be used. It indicates whether the filler metal is suitable for flat, horizontal, vertical, or overhead welding.

- Fourth Digit: 4th digit provides information about the welding current and polarity required for optimal performance. It specifies whether the filler metal is suitable for direct current electrode positive (DCEP), direct current electrode negative (DCEN), or alternating current (AC).

- Suffix: The suffix if applicable (such as -1, -15, -16) provides additional information about the filler metal.

Examples of AWS Numbering system

The numbering system established by the American Welding Society provides valuable information about the properties and usability of electrodes. Let’s take a look at the stick electrode numbering system as an example:

- The prefix “E” indicates that the electrode is meant for arc welding.

- The first two digits of a four-digit number or the first three digits of a five-digit number represent the tensile strength of the electrode. For instance, E7018 has a tensile strength of 70,000 psi, while E10018 indicates a tensile strength of 100,000 psi.

- The second-to-last digit indicates the welding position. “1” signifies that the electrode can be used in all positions, “2” is for flat and horizontal positions, and “3” is for flat, horizontal, vertical down, and overhead positions.

- The last two digits together indicate the type of electrode coating and the recommended polarity. For example, “18” represents an iron powder, low hydrogen coating suitable for use with AC or DC+ polarity.

Here are some examples of specific electrodes and their characteristics:

- E6010: This electrode is designed for DC current only and is commonly used for root bead welding due to its highly penetrating arc. It can be used in all positions.

- E6011: Suitable for all-position AC welding, this electrode has a deep and penetrating arc that allows welding on rusty and dirty metal surfaces.

- E6013: This all-position AC electrode is ideal for welding clean sheet metal. It produces a soft arc with minimal spatter, moderate penetration, and a slag that is easy to clean.

- E7018: Often used with low hydrogen and typically with DC current, this all-position electrode is chosen when high-quality welds are required or when welding difficult-to-weld metals. It produces weld metal with better low-temperature impact properties and offers more uniform results.

By understanding the numbering system, welders can make informed decisions about electrode selection based on the desired tensile strength, welding position, coating type, and polarity. This knowledge helps ensure that the chosen electrode is suitable for the specific welding application, resulting in high-quality welds with the desired properties.

Benefits of AWS Classification System

The AWS classification system offers several benefits to welders and fabricators:

- Standardization: By providing a standardized system, the AWS classifications ensure consistency and compatibility between different filler metals. This allows welders to confidently select the appropriate filler metal for their specific welding applications.

- Easy Identification: The alphanumeric codes used in the AWS classifications make it easy to identify and differentiate between various filler metals. This simplifies the process of selecting the right filler metal for a particular welding project.

- Performance Assurance: The AWS classifications provide valuable information about the mechanical properties and performance characteristics of filler metals. This helps welders ensure that the selected filler metal meets the required strength, ductility, and other performance criteria.

- Application Specificity: The AWS classifications also consider the intended application of the filler metal. For example, certain classifications are designed for specific materials, such as stainless steel or aluminum, or for specialized welding processes like submerged arc welding or gas tungsten arc welding.

Conclusion

The AWS classifications of filler metals serve as a valuable tool for welders and fabricators, enabling them to make informed decisions when selecting and using filler metals. By understanding the alphanumeric codes and their meanings, welders can ensure that the chosen filler metal is compatible with the welding position, current type, and strength requirements of the project.

The AWS classification system promotes standardization, simplifies filler metal identification, and provides assurance of performance and application suitability.