What is Hardness of a material?

Hardness is the resistance with which a material opposes the penetration of another (harder) body or simply says the resistance to deformation (scratching, indentation, and cutting for example) applied in a local area.

Hardness cannot be calculated directly. It is derived from primary measured variables (e.g. testing force, penetration depth, area of impression. Hardness based on its type is both non-destructive testing and destructive testing.

Hardness testing such as Vicker & Rockwell hardness requires the test surface to be prepared by fine polishing to measure the accurate indentation size & hence the material need to be destroyed- So, one can consider it Destructive Testing.

A portable hardness tester (Brinell hardness) can be performed on the actual job with minimal surface preparation can be considered as a Non-Destructive Testing type of hardness.

Hardness testing is a quantitative test method. In metallurgical science, the hardness value of a material is directly related to the type of microstructure. Ferrite is softer while martensitic is a hard microstructure.

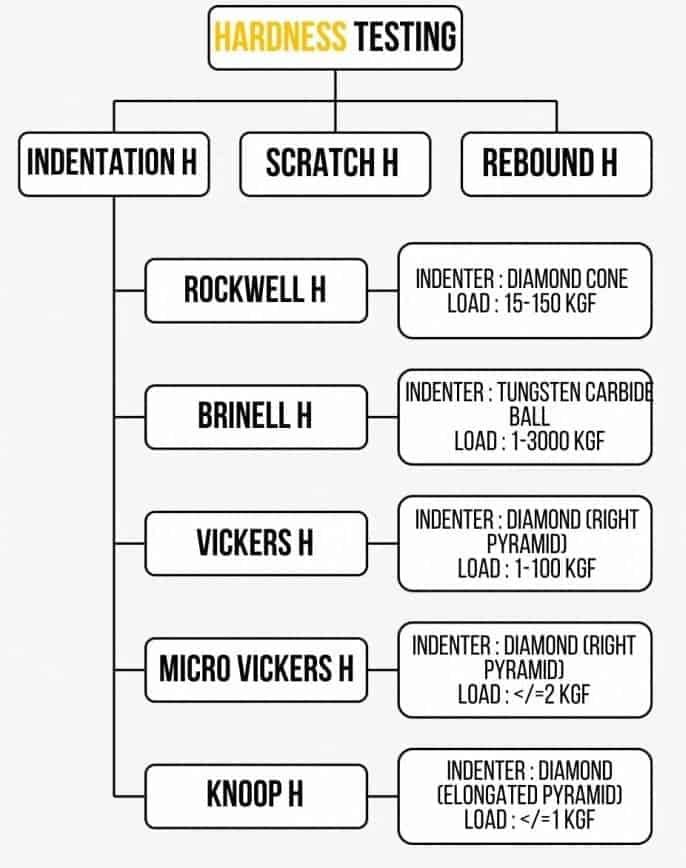

In industries and laboratories, myriad types of hardness testing are performed to meet different sectors, code & standards, and experiments demands. The main types of hardness tests are given in the below picture.

What is Mohs Hardness Test?

Mohs hardness was first invented by Friedrich Mohs (German mineralogist). Mohs Hardness is more like a comparative hardness test where the material is compared for indentation against a known material or hardness value.

10 minerals are ranked on the Mohs scale from low hardness to high hardness from 1 to 10 as shown in the below picture. Mohs hardness is not suitable for engineering fields as the hardness of engineering materials is quite high.

Hardness measurement in Mohs hardness test is done in macro, micro, or nano-scale hardness levels using Mohs Hardness tester. Unit of Mohs hardness is the number 1 to 10 as it is a qualitative test only.

What is Brinell Hardness Test?

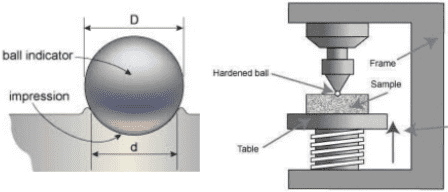

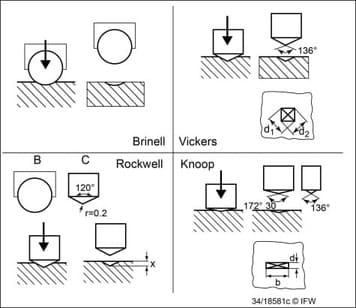

In Brinell Hardness Test, an indenter, a ball made of carbide metal (formerly hardened steel) with diameter D, is pressed in the test object surface and the diameter ‘d’ of the indentation is measured followed the test object force removal.

Brinell hardness HB (according to standard HBW) is proportional to the quotient of the testing force and the surface of the indentation.

The Brinell Hardness test has a limitation of the application to a maximum Brinell hardness of 650 HBW. The unit of Brinell hardness ins HB.

The Brinell hardness tester is used for testing various materials using different test loads and indentor ball diameters.

In America, the Brinell test using a 100 mm diameter indentor with a load of 3000 Kg is used for hardness testing on steel & iron casting while the aluminum load used is 1500 Kg.

Soft materials such as copper and its alloys- Brass & bronze are tested using a 5 -10 millimeters diameter indentor with a 500 Kg load.

The Brinell tests are reported as “75 HB 5/1000/20” which means a Brinell Hardness of 75 was achieved using a 5 millimeters diameter ball with a 1000 kg load applied for 20 seconds.

What is Rockwell Hardness Test?

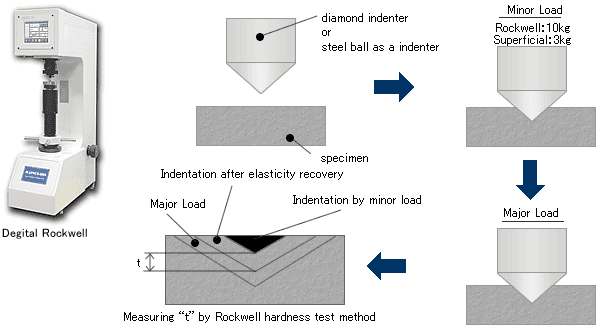

In the Rockwell Hardness test, The indenter – a diamond cone with a rounded tip or a steel sphere – is pressed into the test piece in two stages.

- A minor load of 1o kg at first is applied to make starting indentation and to prevent errors due to surface roughness.

- After that dial is set to Zero and main load is applied to make the indentation. Next, main load is removed & indentation measurement is taken. Note- first load is still not removed at this stage.

The remaining penetration depth tb of this indenter is determined under certain conditions. Rockwell hardness is derived from the penetration depth tb.

Hardness after ROCKWELL is reverse proportional to the penetration depth. Low penetration depths mean high levels of hardening, while high penetration depths are characteristic of soft materials.

The test principle of the Rockwell hardness test is shown in the below figure. The Unit of Rockwell hardness is HRC.

The indentor in Rockwell Hardness is either a steel ball or a spherical diamond-tipped cone having an angle of 120° & 0.2 millimeters tip radius, known as Brale.

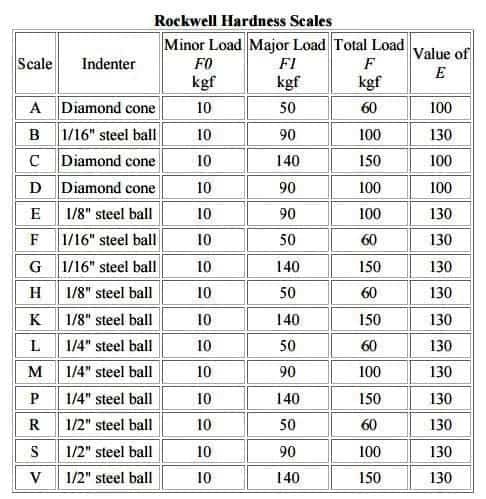

Rockwell Testing uses Rockwell Scale for hardness such as A, B & C. B Scale means the indentor used is a Ball while in Scale A & C diamond indentor is used.

If you see a hardness value reported as 60 HRB, it’s, means the material has a Rockwell hardness of 60 on the B scale, similarly, 60 HRC means the material has a Rockwell hardness of 60 on the C scale.

Different Rockwell Hardness Testing scales are given in the below picture. Scale A is used for very hard materials such as cemented carbides, case hardened material, B & C scale for steel, copper, aluminum, etc, while Scale K to V is for soft materials.

What is Vicker Hardness Test?

The Vickers test runs by pressing a small diamond pyramid of known geometry into a sample with a known load (generally grams or kilograms force, yes those actually have a use) and then measuring the resultant indent to determine its depth.

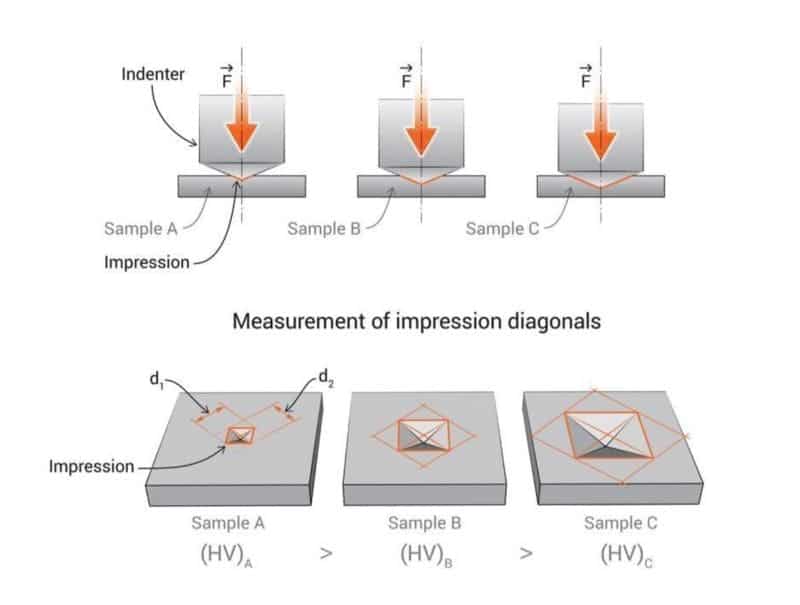

This depth and force can be plugged into a Vickers hardness equation to determine the hardness of the material. In hardness testing, the smaller the indentation, the harder the surface of a material as shown in the below diagram.

Here, sample A has a small indentation compared to samples B & C. So, sample A is the hardest & sample C is the softest material.

What is Rockwell Superficial Hardness Test?

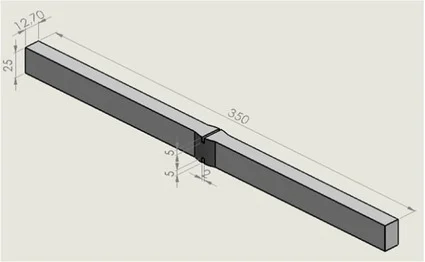

This hardness test type is used for thin sheet materials or components prone to bend or wrap due to normal hardness testing conditions. Rockwell Superficial Hardness Tester uses a regular Rockwell indentor but under reduced test load.

The value of the first load (minor) is 3 KG and the second stage load is 15 or 45 Kg based on the type of indentor. In the Rockwell Superficial Hardness Test letter ‘T’ is added to the hardness value where T means thin material testing.

For example- a hardness value of 25 HR20T means the superficial hardness is 25, a test load of 15 kgs & a steel ball indentor was used.

What is Vickers and Knoop Microhardness Tests?

Both Vickers and Knopp Microhardness tests are used for hardness testing of thin materials, thin-film coatings hardness on the case hardened material surfaces.

Both the tests use a diamond pyramid-shaped indentor & these shape is the only differentiating factors among these two tests.

A square diamond pyramid indentor is used in the Vickers microhardness test while the Knoop hardness test uses a rhombic-shape (diagonal ratio 7.114:1) pyramid indenter.

Vicker hardness indentor has a sharp tip and should not be used for brittle materials otherwise they can result in brittle fracture due to concentrated load.

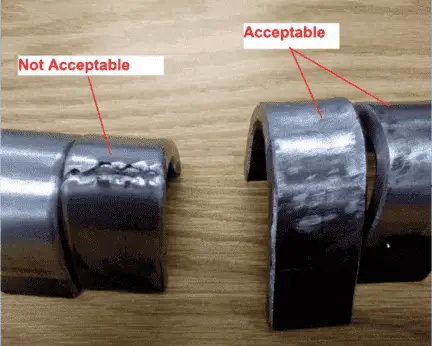

Knopp Hardness indentation is shallower than Vicker. The below picture shows the indentor type for Knoop, Vicker, Brinell, and Rockwell hardness test.

The test load is applied in the range of 10 grams to 1 kilogram which is quite lower than the load values applied in the Vicker Macro Hardness test (48 KG).

Microhardness testing is carried out at higher magnification (up to 1000X) compared to macro hardness testing as the size of indentation is much smaller compared to the former one.

The advance micro hardness testers do not anymore require reading hardness values from the chart. The indentation dimensions measurements are carried out on the machine and locked using a switch and the machine gives the direct reading for the corresponding hardness value.

The units for Vicker hardness is HV and for Knoop Hardness in HK. For example- you may see a Knoop microhardness value as 3000HK25, which means 3000 Knoop Hardness at 25 grams load.

What is Scleroscope and Rebound Hardness Tests?

The Scleroscope test works by releasing a diamond tip hammer from a fixed height on the test surface through a glass tube under its own weight.

The hammer rebound after strike and rebound height is measured on a graduated scale. The scale is divided into 100 parts based on the rebound resulting from high carbon steel.

The hardness number is a direct measurement from the hammer rebound in the tube. Simple, harder the test specimen material, higher the rebound hardness number.

What is Durometer Hardness Test?

A Durometer is used for hardness measurement on elastic materials such as rubber, soft plastics- vinyl, the polyolefin, and fluoro-polymer.

The device uses a calibrated spring to apply defined force to an indenter foot which can be either cone shape or sphere shape.

The depth of indentation is measured by an indicating arrangement. In the market different types of Durometers are available. The most common model A is used for soft materials and Model D is used for hard materials.

What is Barcol Hardness Test?

Barcol hardness test is used for softer materials such as composite materials, thermosetting resins, and plastic to check the condition of their curing.

The test relies on the indentation depth made by the indentor and then compares it to a reference sample or material.

The test sample is placed under the Barcol indentor and pressure is applied until the dial on the gauge touches its maximum reading. Barcol hardness test is a qualitative test only.