What is A-Number in Welding & ASME?

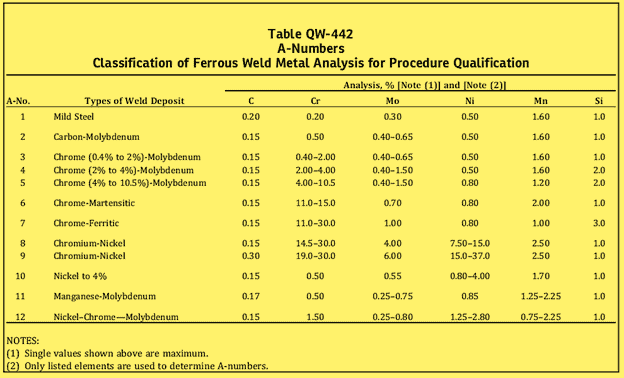

A-Numbers are issued by the ASME to group the weld metal deposit for ferrous materials. A complete list of A-Numbers is specified in BPVC ASME Section 9, Table-QW-442 as shown below. There are a total of 12 different A-Number specified in ASME Section IX.

AWS D1.1 does not use an A-Number system but instead specified ‘Increase in filler metal classification strength’ as an essential welding variable for filler metal.

Generally, the most used ER70S-6, ER70S-2, E6010, E6013, and E7018 rods A-Number are 1. For ER308L, ER316L A-Number is 8. The single value of elements given here is the maximum limit.

Importance of A-Number in Welding

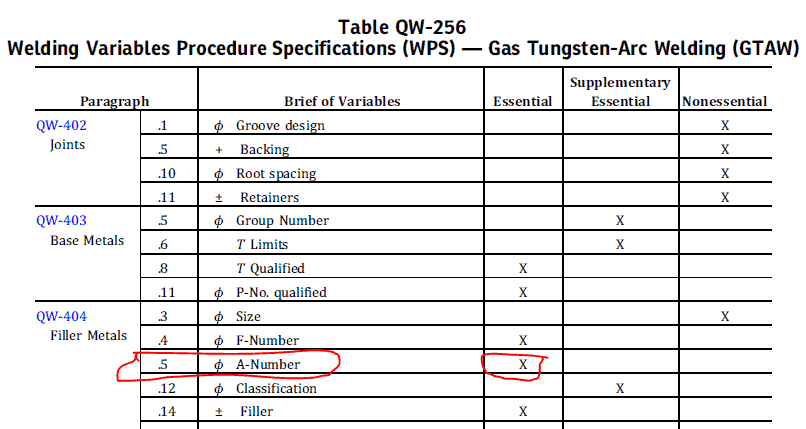

A-Number are applicable for the procedure qualification as they impact the weld metal mechanical properties. So, A-Number is an essential variable for welding processes as listed in Table QW-256.

The below picture shows a reference for the GTAW process. A change in A-Number qualified vs. using other A-Number filler, requires re-qualification of the PQR.

A-Number is not applicable for the performance qualification as they do not affect the soundness of the deposited weld, essential parameters for the performance qualification.

For WQT, F-Number & P-Number are the essential welding variables. A number is only applicable for ferrous metal as we can see in the below table, and hence A-number is not applicable for non-ferrous weld metal deposits such as copper alloys, aluminum, or Nickel base alloys (e.g. Inconel 625).

How A-Number in welding is determined?

You can use the following methods to find out the A-Number for WPS/ Welder Qualification:

- A-Number can be determined based on the filler wire or filler rod chemistry when welding matching base metal. For example, welding ASTM A516 with E7018 or ER70S-6, the A number based on the filler wire chemistry will be 1.

- In other cases, for example, for dissimilar material, the filler wire gets diluted with the base metals chemistry, and hence above method will not work. In these scenarios, a test piece from the welding test coupon needs to be tested for weld deposit chemistry and then review which A-number it is according to ASME Section IX, table QW-442.

Remember, P- Number, & Group Numbers are applied for base metals only. These Numbers are given to group different base materials having matching weldability as defined in ASME Section IX Table QW 422 or AWS D1.1.

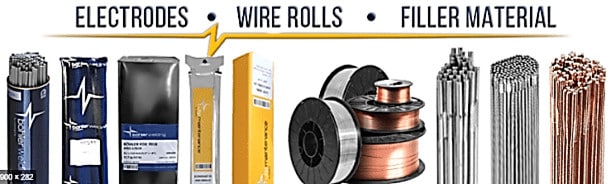

While the F-numbers are relevant for welding consumables (Welding consumables including an electrode, solid wire, cored wires, etc.) grouping purposes and the A-number is for weld deposit chemical composition.

When A-Number are specified in the WPS or PQR, they do not represent the welding electrode/ filler wire chemistry; it refers to the weld deposit chemical compositions.

So, the welding electrode or filler wire and the weld deposit using the same wire will be having different chemistry. This happens due to the dilution that takes place between the welding wire and base material.

What is P-Number in Welding for Materials?

P-Numbers (P mean Parent Metal) in ASME Section IX are provided for users to minimize the numbers of WPS, PQR, and WQT qualifications. In ASME Section IX, Table QW/QB-422 materials are classified as:

- Ferrous Metals

- Non-Ferrous Metals

For Ferrous metals only, ASME Section IX provided Group Numbers in Table QW/QB-422. Material having Group Numbers means that they have toughness requirements.

The base metals are assigned specific P-Number based on their chemical and mechanical properties. E.g., P-Number 1 is for C-Mn (Carbon Manganese) or Low Carbon Steel materials.

P-Number is an Essential variable for Welding Procedure Qualification according to ASME Section IX.

Related Reading: What is P-Number in Welding and ASME & P-Number pdf chart?

What is F-Number in Welding for Electrode & Filler Wire?

F- Numbers are given based on the usability characteristics (defined in ASME Section IIC, SFA 5.1 for example for carbon steel SMAW electrodes) and metallurgy of the welding filler metal in BPVC ASME Part-9 and AWS D1.1.

Related Reading: What is ASME F-Number for filler metals?