Welding Grade 5 and 8 Bolts

Grade 8 bolts are one of the most commonly used high strength types of industrial fasteners. Made from medium carbon alloy steel, Grade 8 bolts offer superior strength and durability.

With a maximum tensile strength of 150,000 PSI and minimum yield strength of 120,000 PSI, these bolts can be used to secure heavy machinery or large structures in almost any environment. Additionally, their anti-corrosion properties make them perfect for use in high moisture areas like coastal regions.

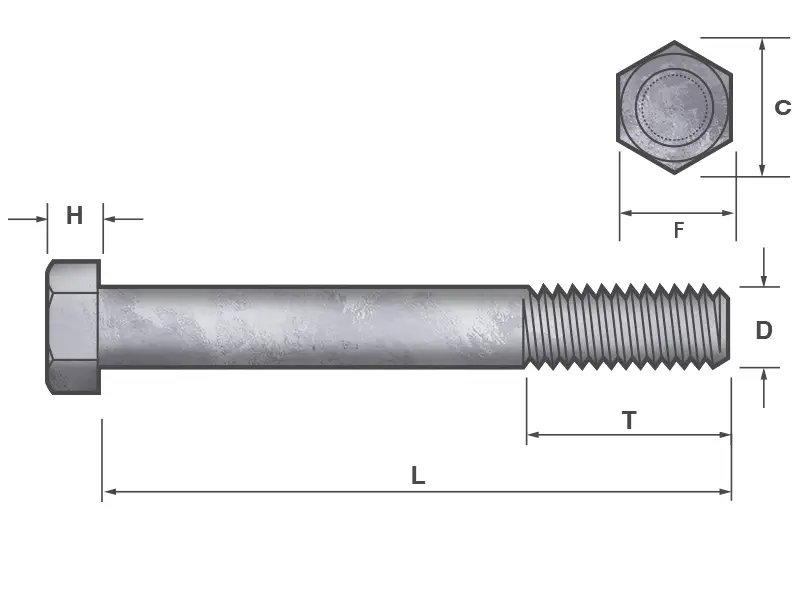

These versatile bolts come in several sizes ranging from ¼ inch up to 1 ½ inches and can be found with either coarse threads or fine threads depending on the application.

A black oxide finish ensures that they look great even when exposed to harsh environmental conditions while meeting all ASTM standards for grade 8 fasteners.

Grade 8 Bolt Specification

Grade 8 Bolt Specification is SAE J429.

Grade 8 Bolt chemical Composition

| Grade | Specs | Carbon | P | S |

|---|---|---|---|---|

| 8 | SAE J429 | 0.28-0.55 | 0.030 | 0.050 |

Welding of Grade 8 Bolt

Grade 8 bolts have higher tensile strength than other grades of bolts and are used when strong connections are required.

Welding these bolts can be tricky due to their increased hardness and high tensile strength. It’s important to use the proper welding processes and techniques to ensure a satisfactory welded joint.

It’s important to use an appropriate filler material when joining grade 8 bolts together since they may require additional hardness or other properties that can only be provided by specific types of fillers.

First, decide the purpose of your welding.

- Is it just to attach it?

- Or, the weld is for strength purposes?

In case you just want to weld it for attachment objectives, there are not much challenge. You can use E7018 rod and weld using stick welding or ER70S-6 TIG Welding.

Welding Grade 8 bolt for strength objective is challenging. As mentioned earlier, the strength of Grade 8 bolt is very high, and no matching consumables are available in this strength range.

So, my advice, don’t weld it if the main load is going to be on the weld.

In case you still need to do welding, keep in mind, the weld can break at the welding point depending on the strength of the filler wire. For a nearby weld strength, you can use E10018-D2 welding rod.

This will give you a minimum weld strength of 100 Ksi (100,000 psi), although still lower than 150 ksi or bolt strength.

Welding with E10018-D2 does not require any post weld heat treatment and you will be good to proceed as weld.

The above same guidelines are applicable for grade 5 bolt too.

Will welding grade 8 bolt weaken it?

will welding grade 8 bolt weaken it- this is a common question that comes in mind when we plan to weld these high strength ultimate bolts.

Definitely, welding is going to create a heat affected zone (HAZ) if you weld any material and its the same case here too.

Apart from above, the strength of the weld will be less compared to the Grade 8 bolt strength as explained earlier.

So, before you commence the welding, keep this in mind.