Types of Tungsten Electrodes

Tungsten can work in a high-temperature environment, which positively distinguishes it from other metals. Knowing different types of Tungsten Electrodes is very helpful for welders to choose the right one for their job.

In addition, it has another remarkable ability: not to be soft when its hot. The addition of alloying components (e.g., Thorium, Zirconium, etc.) expands the possibilities of using these products.

In TIG Welding (GTAW) the choice of suitable non-consumable electrode material is limited by the need to meet some demanding welding operating conditions. The electrode material chosen must satisfy the following requirements:

- high electrical conductivity

- high thermal conductivity

- high melting point

- good emissivity

- good thermal fatigue properties

- limited erosion

Materials that possess some of these properties are; carbon, tantalum, and tungsten but the tungsten, which has a melting point of 3410°C, provides the most satisfactory compromise between cost and performance. Carbon has poor mechanical strength and low erosion resistance and tantalum is too costly.

Pure tungsten (W) offers valuable properties (E.g. high melting point, high density, and ease of doping with other elements) that make it the most important element for TIG & Plasma welding electrodes.

Further, with the addition of other doping elements such as Cerium (Ce), Thorium (Th) and many more improve these properties to a higher level.

For TIG welding (GTAW) for carbon steel, aluminum, stainless steel, and other reactive metals, tungsten electrodes are classified in the AWS A5.12- Specification for tungsten & oxide dispersed tungsten electrodes for arc welding & cutting.

Tungsten electrodes are divided into two groups: for operation on direct and alternating current. They are also classified and marked according to the international standard EN 26848.

Following are the main type of tungsten rods used in TIG Welding as per the AWS A 5.12 Specification:

- Pure tungsten, (designation as EWP)

- 1% thorium tungsten, (designation as EWTh-1)

- 2% thorium tungsten, (designation as EWTh-2)

- 1/4% to 1/2% zirconium tungsten, (designation as EWZr)

- 2% Cerium tungsten, (designation as EWCe-2)

- 1% Lanthanum tungsten, (designation as EWLa-1)

- Alloy not specified, (designation as EWG)

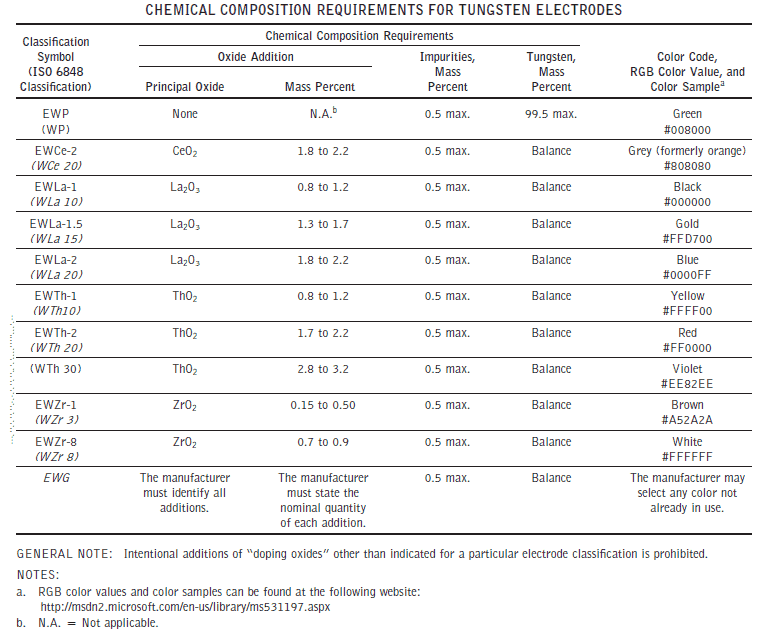

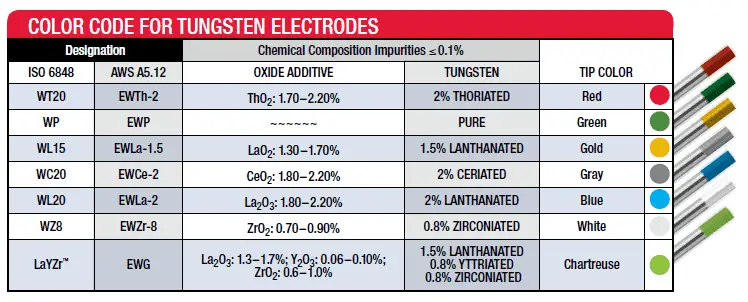

Types, Color Coding, ISO 6848 & AWSA5.12 Designations of Tungsten electrodes for TIG Welding

Tungsten Electrodes for TIG/ Plasma Welding are classified and designated according to the AWS A5.12 and ISO 6848 Standard.

A summary of tungsten electrode designation, type of oxide, and tip color is given in the below picture for reference.

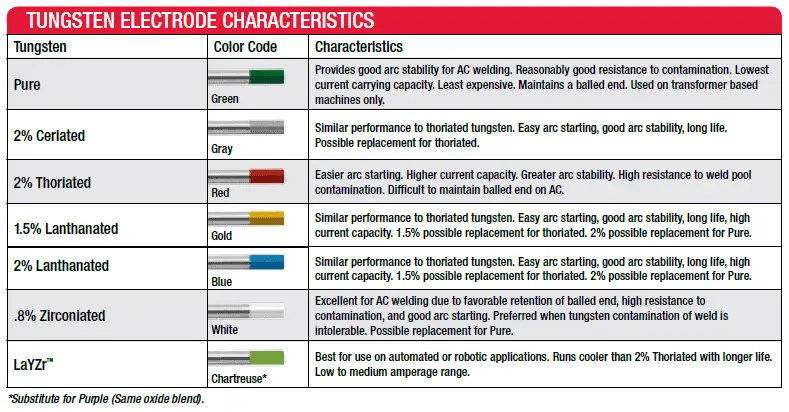

Thoriated Tungsten, EWTh-1 and EWTh-2

Thorium oxide (ThO2) is added to Thoriated Tungsten electrodes. The electrodes are added 1.7 to 2.2% of ThO2 to improve current carrying capacity and electron emission (this helps to carry 20% more welding current).

The addition of Thorium oxide (ThO2) also increases the life of the tungsten electrode (it can withstand high temperature & current) during welding compared to pure tungsten electrode.

Thorium oxide (ThO2) works very well with Straight polarity (DCEN) and is used for welding carbon steel, stainless steel, aluminum, copper alloys, and other materials.

Buy Online TIG Welding Tungsten Electrodes 2% Thoriated

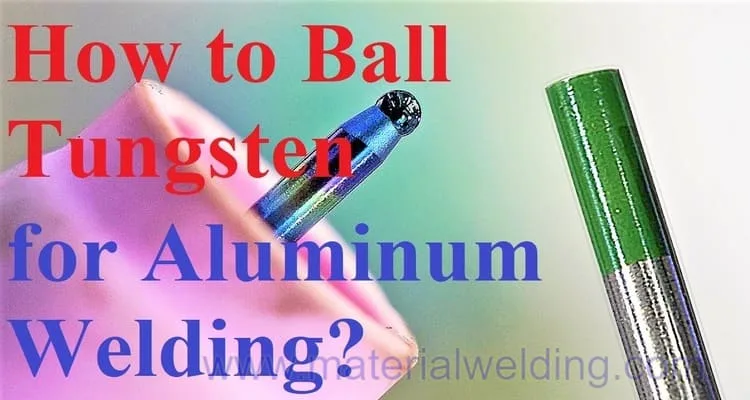

Thoriated tungsten electrodes are not suitable for Alternating current (AC) polarity. The reason is that with AC, the tungsten rod needs to have a round balled end, and with thoriated it’s difficult to maintain.

Pure Tungsten, EWP Welding Electrode

Pure tungsten TIG welding electrode has very low heat resistance and electron emission properties in all other types of tungsten electrodes.

This restricts the use of pure tungsten electrodes only for welding aluminum and magnesium alloys where it is beneficial to remove the hard oxide layer by cleaning action. The working life of pure tungsten electrodes is short.

Buy Online TIG Welding Tungsten Electrode Pure Tungsten at Best price

Lanthanum Tungsten, EWLa-1.5 & 2

Lanthanum oxide (La2O3) in about 1%-2% concentration is added to tungsten electrodes. Lanthanum oxide tungsten’s are not radioactive and hence safe to use as per safety requirements.

They have current-carrying properties similar to thoriated tungsten electrodes, except that they have a slightly higher arc voltage than thorium and cerium tungsten’s.

Buy online TIG Welding Tungsten Electrodes 2% Lanthanated at best Price

Cerium Tungsten, EWCe-2

The addition of Cerium oxide (CeO2) by 2% to tungsten increases the current-carrying capacity similar to the thoriated electrode.

Ceriated tungsten electrodes are developed in place of the thoriated electrodes as a safe alternative. They provide better arc stability and good arc-starting.

The life of Ceriated electrodes is also longer similar to thoriated tungsten electrodes. These tungsten electrodes can be used for DCEP, DCEN, and AC polarity.

Zirconium Tungsten, EWZr-8

Zirconium oxide (ZrO2) is added to tungsten to make the Zirconium Tungsten electrode. Zirconium oxide (ZrO2) helps tungsten emit electrons freely.

Zirconium oxide (ZrO2) has similar effects like Thorium but to a lesser extent. Because zirconium tungsten’s are more easily melted than thorium tungsten, ZrO2 electrodes can be used with both AC and DC currents.

Due to the difficulty in getting the desired balled end on thorium vs. zirconium tungsten, a Zirconated electrode is used for AC welding of aluminum and magnesium alloys.

Buy Online TIG Welding Tungsten Electrodes 0.8% Zirconiated at best price

Alloy Not Specified, EWG

The EWG classification is for tungsten electrodes means that the manufacturer can make their own electrode with the modified percentage of doping elements.

You can consider them similar to ER70S-G welding wire where wire manufacturers can choose the wire chemistry. EWG-designated electrodes are rarely used in TIG welding applications.

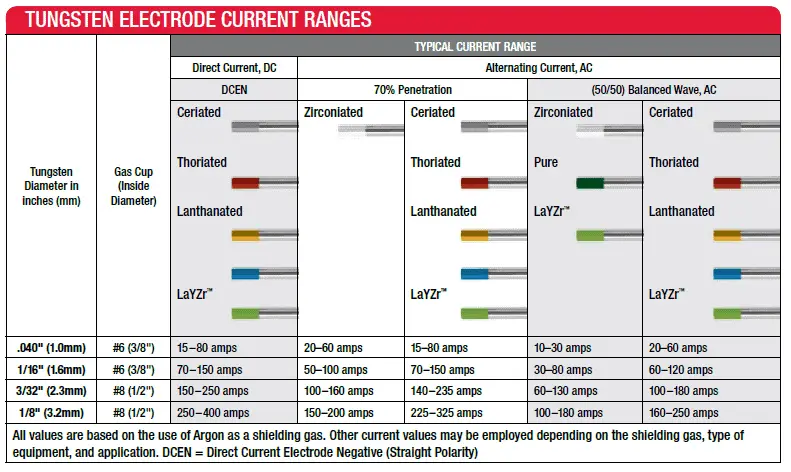

The current range for different types of Tungsten electrode

The current carrying capacity of tungsten electrode depends upon:

- Types of the tungsten electrodes.

- Type of shielding gas.

- Type of welding polarity.

- Type of equipment.

The below figure shows the various types of tungsten electrodes and their current carrying capacity.

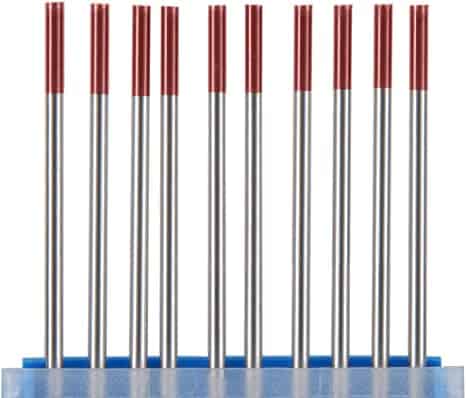

Characteristics of Tungsten Electrode & color-coding of tungsten electrode

Color codes of tungsten electrodes are shown in the below figure.

Here Green color is for pure tungsten electrode TIG welding, Gray for 2% Ceriated tungsten rod for TIG Welding, Red for 2% thoriated tungsten electrode TIG welding, Gold & blue are for Lanthanated tungsten electrode TIG welding, and White for Zirconated tungsten electrode TIG welding as shown below.

Applications of Tungsten Welding Electrodes

Knowing the areas of application of certain types of tungsten electrodes, as well as their features, will help you make the right choice for Quality TIG Welds.

Each type of Tungsten welding electrode is created with a specific purpose that determines the types of production welding in which they are used:

- Electrodes without alloying (Green Color) are used for welding nickel, aluminum.

- EWCe-2 (ceriated) electrodes are used for welding tantalum, molybdenum, high alloy steels, titanium, nickel, copper.

- Electrodes marked EWLa-2 (Lanthanated) can be used for metal spraying and plasma welding of ordinary and stainless steels in an argon environment, using alternating or direct current of direct polarity.

- EWZr-8 (Zirconated) electrodes can weld nickel, aluminum, magnesium and their alloys in argon.

- EWTh-2 (Thoriated) red tip electrodes are needed for welding copper, nickel, titanium and high alloy steels. They are distinguished by good arc start and long service life, but can be hazardous to health if inhaled by welding gases and aerosols.

Advantages of Tungsten Welding Electrodes

Non-consumable tungsten electrode has the following advantages:

- stable welding arc;

- the presence of a wide range with different characteristics;

- long working time;

- high economic efficiency of application.