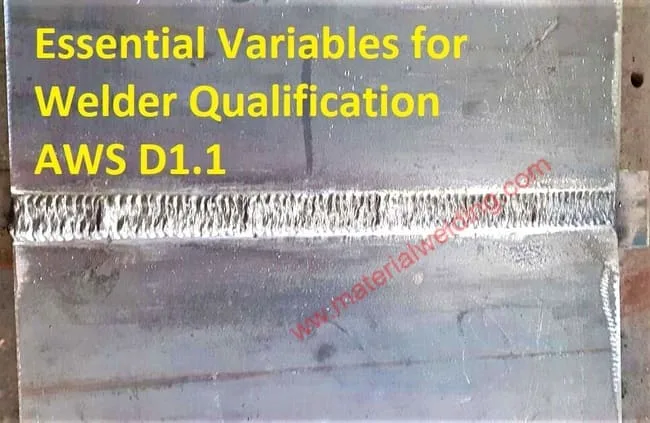

Pipe Welding Positions: What You Need to Know

Pipe welding positions are essential to know in order to be a proficient welder. Pipe welding can be a very lucrative career, but it’s important to learn about the different welding positions available to you. Some welders only know how to weld in the flat position, which limits the types of pipes they can work on.

There are many different types of welds that can be used in pipe welding, and the position of the welder is important to the quality of the weld. In some cases, the welder may be able to stand while welding, but in other cases, they will need to be in a specific position in order to get the best weld possible.

Knowing all types of Pipe Welding Positions will enhance a Welders welding experience, skills and provide path to earn higher salaries.

Note: Link to Download Welding Charts given at the end of the this post.

Pipe Welding Positions for Groove Weld

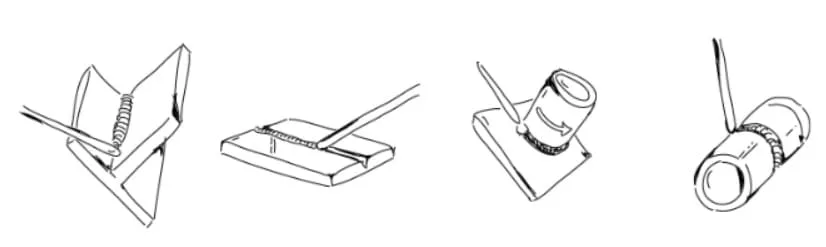

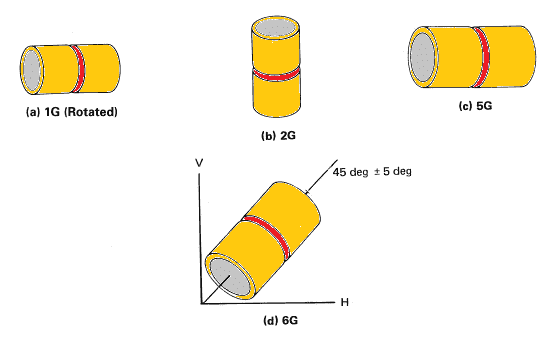

Welding positions for Pipe are different than the plate. Test positions for pipe welding that are used for welder ticket/ WQT qualification are given in the below picture.

Test positions 3G & 4G are not applicable for pipe and they are only used for plate welding. In addition, 5G and 6G positions are only applicable for pipe welding.

5 Main Different Types of Pipe Welding Positions

Pipe Welding Positions are similar to Plate Welding Positions, exception are that there are no 3G & 4G Welding Positions applicable for Pipe Welding.

In summary, The main 5 Pipe Welding Positions for Groove (Butt) Weld (Fillet weld explained later in this article) are:

- 1G (Pipe rotates) Welding Position-Flat Pipe Welding Position.

- 2G Welding Position-Horizontal Pipe Welding Position.

- 5G Welding Position-Vertical Uphill Pipe Welding Position.

- 6G Welding Position-Inclined Pipe Welding Position.

- 6GR Welding Position-Restricted Inclined Pipe Welding Position.

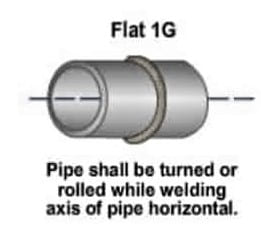

What is a 1G Pipe Welding Position (Flat Pipe Welding Position)?

A 1G Pipe Welding Position (shown in the above figure) is a flat welding position for pipe Welding where pipe rotates during welding to keep the welding torch position in Flat Position. It is also called horizontal rolled position in the non-standard definition.

1G welding position is used for pipe welding to carry out circumferential welding (usually groove welds). The pipe axis is horizontal and the pipe is rolled so that the welding position remains flat.

This Welding Position is mainly used for robotic welding of pipes, cylinders, and welding of circumferential seams in vessels & tanks construction in 1G Weld position.

What is a 2G Pipe Welding Position (Horizontal Pipe Welding Position)?

The 2G Pipe Welding Position is used for circumferential seams welding for groove weld of pipe where pipe axis is in the vertical position and weld axis remains in the horizontal plane.

Welding is carried out in a horizontal position. Usually, the pipe is not rolled although there is no limitation. The pipe setup of the 2G welding position is shown in the above picture.

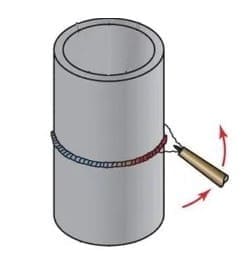

What is a 5G Pipe Welding Position (Vertical Uphill Pipe Welding Position)?

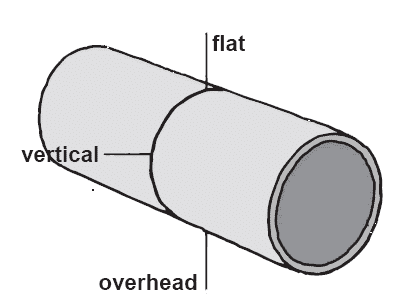

5G Welding Position is applicable for Pipes only. In a 5G Welding Position, the pipe axis is kept horizontal plane (similar to a 1G Welding Position), and the pipe remains fixed (not rotated like 1G) till the welding joint is completed.

The welder performs the welding all around the pipe covering Flat, Horizontal, Vertical, and Overhead welding positions combinations. During Vertical welding, the welder can use either uphill progression or downhill progression.

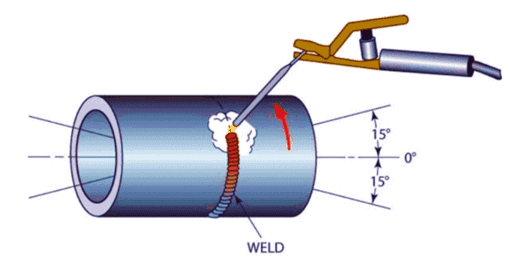

What is a 6G Pipe Welding Position (Inclined Pipe Welding Position)?

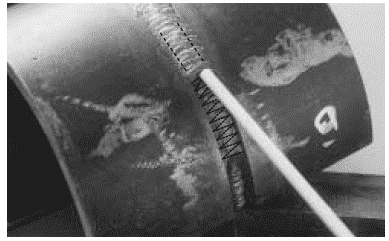

6G Welding Position is applicable for pipe circumferential groove welding only. The pipe axis is inclined at 45° from the horizontal plane.

The pipe is not rotated until the welding is finished and the welder performs the welding from all around covering flat, horizontal, vertical, and overhead positions combined in a single pipe joint.

A 6G welding position for an actual weld joint is shown in the below picture.

What is the 6GR Pipe Welding Position (Restricted Inclined Pipe Welding Position)?

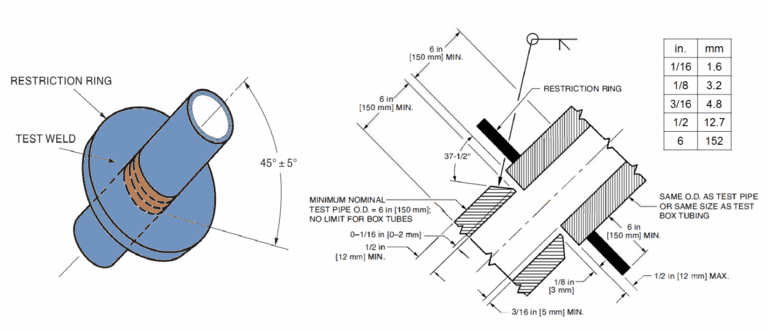

6GR Welding Position is similar to 6G welding in terms of weld axis and pipe axis. Although, in the 6GR position, only one pipe is having weld bevel preparation and an additional restriction ring is added to the test piece.

This ring regulates the welding access for the welder to test their skills to deposit a sound weld. A setup of the 6GR Welding Position is shown in the below figure.

6GR welding position is mainly applicable for offshore welding structures. Click the below link to learn about the 6GR welding position in depth.

What is the 6GR welding Test position? 6GR welding test tips and welder qualification

Pipe Welding Positions for Fillet Welds

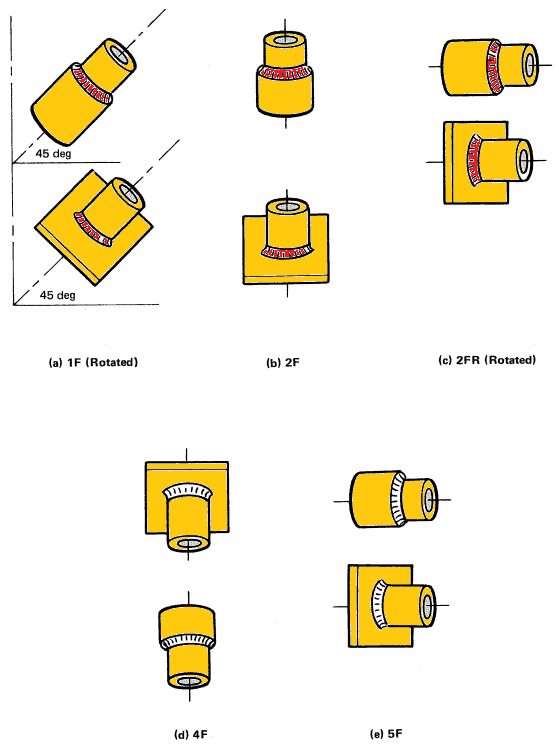

There are fillet Welding Positions that are applicable for the pipe to pipe and pipe-to-plate welding. The main 5 Fillet Welding Positions for Pipe are:

- 1F (pipe rotates) Welding Position.

- 2F Welding Position.

- 2FR (Pipe rotates) Welding Position.

- 4F Welding Position.

- 5F Welding Position.

These pipe weld positions which are applicable in combination with pipe to pipe or pipe to the plate are shown in the below picture.

In the 1F, pipe welding position, the pipe is inclined at 45 degrees and rotates around its axis during welding.

In 2FR Welding Position, the pipe is placed horizontal and arranged as a lap weld between two pipes, or a pipe welded transverse to the plate face is used. The test coupon rotates during the welding.

Pipe Welding Positions chart.pdf

A Pipe Welding Positions Chart is very useful for learning welding positions. You can print it and keep on display in welding shop & welding training centers. Below is the links for high definitions (HD) welding positions charts.

You can download Pipe Welding Positions chart HD Quality.pdf (Courtesy: Lincoln Electric– Market leader in Welding Products & Machines) to guide in your welding career.

Download EN ISO 6947 Welding Positions Chart.pdf (Reference: Messers).

Pipe Welding Positions Symbols

Pipe Welding Positions along with their Weld information Symbol & Equivalent ISO 6947 welding positions are given in the below table for reference.

| Welding Position Symbol | Welding Position (ASME) | Welding Position (ISO 6947) | Weld Types |

| 1G | Flat | PA | Groove Weld |

| 2G | Horizontal | PC | Groove Weld |

| 5G | Pipe Position-Vertical Uphill | PH | Groove Weld |

| 6G | Pipe Position-Inclined | H-L045, J-L045 | Groove Weld |

| 6GR | Pipe Position-Restricted Inclined | Not Covered | Groove Weld |

| 1F | Flat | PA | Fillet Weld |

| 2F | Horizontal vertical position | PB | Fillet Weld |

| 2FR | Horizontal vertical position | PB | Fillet Weld |

| 4F | Overhead | PD | Fillet Weld |

| 5F | Vertical Downhill/Uphill | PG/PF | Fillet Weld |

Similar Posts:

- What is the 6GR welding Test position? 6GR welding test tips and welder qualification

- 5G Welding Position tips & tricks

- Overhead Welding tips and technique for Stick and MIG welding

- 1G,2G,3G,4G-Plate Welding Positions Chart-Easy Understanding

- How to Weld & pass a pipe 6G Welding Position test

- How to Choose the Right Stick Welding Electrode and Rod Type