This complete guide on ”How to weld Brass covers brass welding with Stick Welding, TIG Welding, MIG Welding, electrode & filler wire selection, preheat & interpass temperature, PWHT requirements, etc.”.

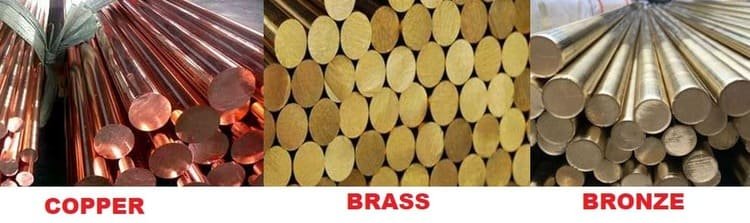

What is Brass?

Brass is an alloy of Copper (Cu) & Zinc (Zn) metals. They are also known as Copper-Zinc alloys in engineering applications. The main brass grades are- C2100, C2200, C2300, C2400, C2600, C2680, C2720 and C2801.

In brass, zinc is one of the main alloying elements although zinc fuming is a critical safety issue when welding brass.

These alloys, popularly known as brasses, have the largest commercial application among copper alloys. Zinc is soluble in copper to the extent of 37% at room temperature and 32.5% at Q25°C. Low-zinc brasses have Zn content ranging between 5 and 20%, while high-zinc brasses have Zn content between 30% and 40%. The 60-40 brass is known as Muntz metal.

The addition of Zn to Cu increases strength, hardness, and ductility. It lowers the melting point, density, and electrical and thermal conductivities. The color of the alloy also changes with the zinc content. With increasing Zn, the alloy comes closer to gold in color.

During welding, zinc vaporizes when brass is melted & this affects the weldability of brass. The issue is concerning when welding high zinc-based brass alloys. The welder must wear full PPE, especially respiratory masks and hoods.

Can you Weld Brass?

In layman’s words- Yes, brass can be welded successfully with stick welding, TIG, MIG, and gas welding & this post guide you on How to Weld brass effectively.

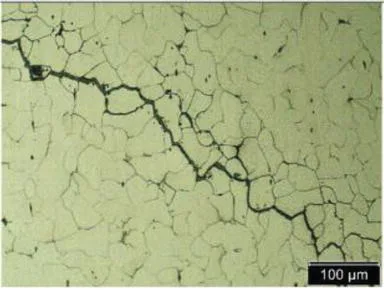

The main issue with brass welding is:- Zinc vaporization effect brass weldability, which can result in porosity and lack of fusion.

Zinc when evaporate create gaseous pressure and these gases when came out of the weld puddle, create pores. So, brass alloys with less zinc content have good weldability compared to ones with high zinc content.

Continue this post to learn about different techniques & welding processes for welding brass to brass, brass to copper, brass to steel, and brass to stainless steel welding.

Can you Weld Brass to steel?

Yes, it is possible to achieve a good welding joint quality for welding brass to steel. The selection of welding electrode or filler wire for brass to steel welding is mainly ERCuAl-A2 or ECuAl-A2. Although this can vary based on the actual grade of the brass.

Continue reading this post to learn the best Stick welding electrodes or TIG MIG Filler wire for Brass to Steel Welding applications.

Can brass be welded to stainless steel?

es, it is possible to achieve a good welding joint quality for welding brass to Stainless steel.

The selection of welding electrode or filler wire for brass to steel welding is mainly ERCuAl-A2 or ECuAl-A2. Although this can vary based on the actual grade of the brass.

Continue reading this post to learn the best Stick welding electrodes or TIG MIG Filler wire for Brass to Stainless Steel Welding applications.

Brass Welding Processes & Machine

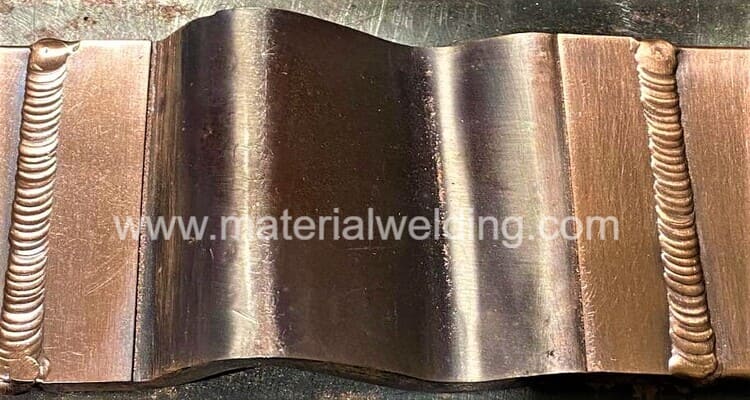

Brass is generally welded with TIG (GTAW) and MIG (GMAW) welding as Stick Welding or SMAW welding gives poor performance. Stick Welding needs a wider groove angle for achieving full joint penetration and is prone to slag entrapment.

Overall TIG welding is good as it gives good control on the weld pool and shallower penetration. TIG welds are highly clean when compared to Stick welding or MIG Welding and have better quality with a very good bead appearance.

Brass Welding Rod and wire

Due to the zinc vaporization issue, a matching filler wire/ rod is not available for brass welding.

Also, zinc vaporization amount varies with the amount of welding heat input, a precise weld deposit analysis is generally not possible.

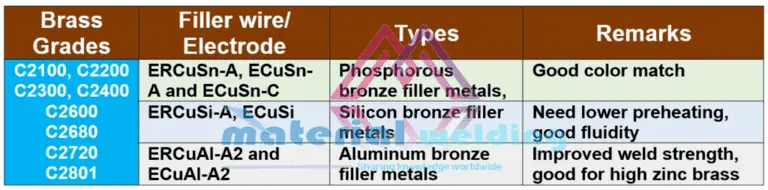

The below table summarizes the various types of filler metals available in the market and their characteristics.

| Image | Product | Details | Price |

|---|---|---|---|

| Blue Demon brand ERCuAl-A2 X 1/16″ X 36″ X 1LB TIG TIG Rod | Wire Specification: ERCuAl-A2 Wire Dia: 1/16” TIG Welding Filler | CHECK PRICE |

| ERCuAl-A2 MIG Welding Wire | Wire Specification: ERCuAl-A2 Wire Dia: .045” MIG Welding Wire Spool | CHECK PRICE |

| ERCuSi-A Silicon Bronze TIG Welding Rod – 36″ x 1/16″- (1 Lb) | ERCuSi-A Wire Dia; 1/16” TIG Welding Filler Wire | CHECK PRICE |

| ERCuSi-A X .030 X 2LB Spool Welding Wire | ERCuSi-A Wire Dia; 0.30” MIG Welding Wire Spool | CHECK PRICE |

Welding of Brass to Brass

Stick Welding or SMAW of brass (Brass to Brass Welding) grades C2100, C2200, C2300, C2400, C2600, C2680, C2720 and C2801 is done using ECuSn-a, ECuSn-C, and ECuAl-A2 type rod. Stick welding rods do not require any baking before use.

Related Reading: Copper Welding Guide.

It is good practice to keep the brass welding rods in a holding oven maintained at a temperature of 80 to 100 Deg C.

Welding of C2100, C2200, C2300, C2400, C2600, C2680, C2720, and C2801 can be done using a Stick welding rod ECuSn-A, ECuSn-C, ECuSi, and ECuAl-A2.

TIG or MIG welding of C2100, C2200, C2300, C2400, C2600, C2680, C2720, and C2801 can be done using ERCuSn-A, ERCuSn-C, ERCuSi, and ERCuAl-A2 type filler wire. Properties of these filler wire/ rod weld deposits are given in the above table for reference.

TIG/ MIG Welding of Brass to Brass

TIG and MIG welding rod for brass to brass grades C2100, C2200, C2300, C2400, C2600, C2680, C2720, and C2801 is ERCuSn-A, ERCuSi-A, and ERCuAl-A2. ERCuAl-A2 is a versatile brass welding rod and can also be used for welding brass to carbon steel and stainless steel applications.

Pure argon is used for shielding when welding the brass. A mixture of Argon + Helium can also be used for brass welding applications.

Adding helium to the argon gives deeper penetration. When welding, open root on butt weld in piping, purging is required. Usually, pure argon gas is used for purging applications.

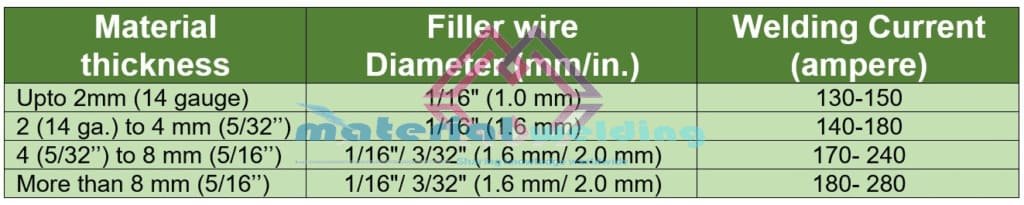

Welding current For TIG & MIG welding of brass

Recommended welding current for TIG and MIG Welding of brass is given in the below table. for material thickness up to 2 mm or 14 gauge sheet, a welding current of 130 to 150 ampere is required. Brass welding needs high welding current because of the high thermal conductivity of the brass.

So, high heat is necessary to make a good fusion during welding. For thickness ranging from 14 gauges to 5/32 inches, a welding current of 140 to 180 ampere is recommended.

Which are the Shielding Gases for Brass TIG/ MIG Welding?

Pure argon is used as shielding gas for TIG & MIG welding of brass and its alloys. For gas purity and dew point requirements, refer to the AWS A 5.32 specification.

Helium is sometimes used as a shielding gas either in its pure form or mixed with argon to enhance penetration when welding brass. Click the below link to learn the difference between shielding, purging, and trailing gas.

Difference between gas shielding, gas purging & gas trailing?

How much to Preheat the Brass for welding/ brazing?

Low zinc brass shall be preheated at 100 to 350°C. Brass with high zinc shall be preheated to a lower range to avoid zinc fuming. Preheating is generally not required for thin plate welding.

When welding thick brass plate or cast brass, preheating is necessary to achieve good fusion, Due to the high thermal conductivity of brass, by preheating heat losses are reduced.

Copper and some of its alloys possess high thermal conductivity, with the result that during welding heat is rapidly conducted away from the joint to the surrounding base metal. Such heat loss from the joint depends on the thickness or mass of the base metal and its temperature.

When the heat loss is too rapid, it slows down the welding speed and may even cause a lack of fusion and porosity. Heat loss can be minimized by preheating the base metal.

The optimum preheat temperature depends on the type of alloy, metal thickness or mass, and the heat input rate of the welding process. TIG or MIG welding with helium instead of argon as a shielding gas requires less preheat due to the high arc voltages developed in the process.

MIG welding with argon requires less preheat than TIG welding with argon because it generates more heat in the arc.

Post Weld heat treatment (PWHT) of Brass Welds

The need to heat-treat a welded fabrication depends on the base metal composition and service application.

Precipitation-hardening type alloys are heat-treated after welding to remove the variations of hardness in the weld area, which occur as a result of aging or over-aging caused by the welding heat.

Weldments which are prone to stress corrosion cracking in certain environments must be stress-relieved.

Stress-relieving temperatures for some of the copper alloys which are particularly susceptible to this defect are given in Table 10.42. Heating should be gradual and the weldment should be held at the temperature for at least one hour.

How to Weld Brass: Welding of brass to Carbon steel

Brass (C2100, C2200, C2300, C2400, C2600, C2680, C2720, and C2801) to carbon steel shall be welded with ERCuSi-A type filler wire.

A buttering on both the weld faces shall be made prior to the joining. Preheat the brass to 100 to 350°C temperature prior to the buttering. No preheating is required for the carbon steel.

Welding can also be carried out using ERCuAl-A2 type filler wire using TIG Welding or MIG Welding process. ERCuAl-A2 gives good fusion when used to joint brass to carbon steel material.

Successful Welding tips when welding Brass

- Always direct the arc on the welding pool. This technique will minimize the melting of base metal thus lowering the zinc fuming.

- Directing the arc to the weld pool also minimizes the penetration.

- Clean the brass surface from any impurities such as oil, moisture, or dust.

- Use a large bevel angle for weld joint if welding using the SMAW process.

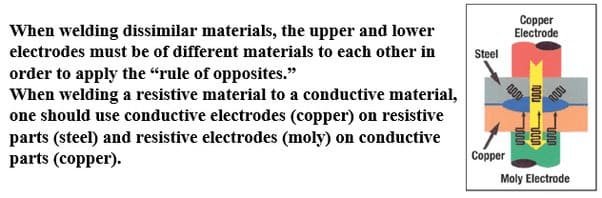

How to Weld Brass: Spot welding copper to brass

Spot welding of brass to copper is carried out using a conventional spot welding machine using the right electrode.

How to Weld Brass: Welding brass with oxy-acetylene

Gas welding or oxy-acetylene welding of brass if required is carried out using a Cu 5180 (CuSn6P) type rod. However, gas welding or brass is not recommended as during gas welding due to heat, zinc will vaporize. This zinc vaporization will produce a lot of fumes & result in porosity.

In oxyacetylene welding with a reducing lame, an oxide film forms over the molten pool, which suppresses the volatilization of zinc, provided the weld-metal is not overheated.

Brass gas welding rods are designed to contain about 40% Zn, so that the weld metal has a good proportion of the hard and strong beta-phase, which is soft and ductile at elevated temperatures, prevents weld cracking.