There are numerous types of Stainless steels and grades that you may deal in day to day life. How you can know the right grades and types of stainless steels you are using?

Well, this post covers everything you need to know to master your knowledge about stainless steel material, its metallurgy, its types and their properties.

What is Stainless Steel?

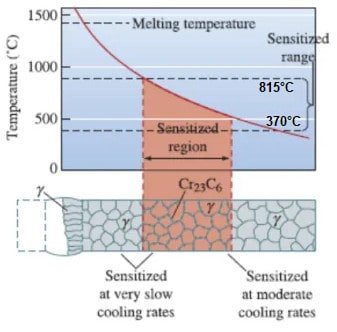

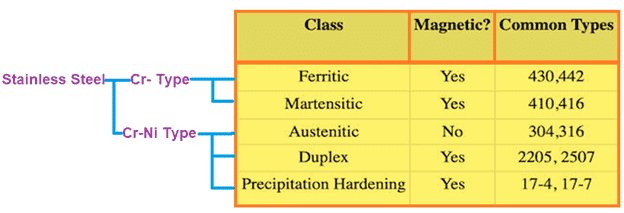

Stainless steel is a broader term covering austenitic, ferritic, martensitic, ferritic-austenitic (Duplex) and precipitation hardened stainless steels. Each of its types has unique properties and applications & unique microstructures. Some stainless steel responds to heat treatment while some do not.

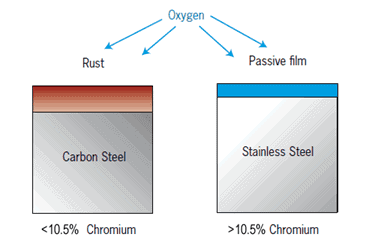

Naturally iron (Carbon steel) is reactive to oxygen. Iron reacts with oxygen and converts to iron oxide as rust. But when carbon steel is added with a minimum of 10.5% chromium, chrome forms a passive layer on the material surface to protect it from rust and corrosion as explained in the below picture.

Grades and Types of Stainless Steels

Stainless steels are divided into 5 main types (grades):

- Ferritic Stainless steel

- Austenitic Stainless Steel

- Martensitic Stainless Steel

- Duplex Stainless Steel

- Precipitation hardened (PH) Stainless Steel

What is Austenitic Stainless Steel?

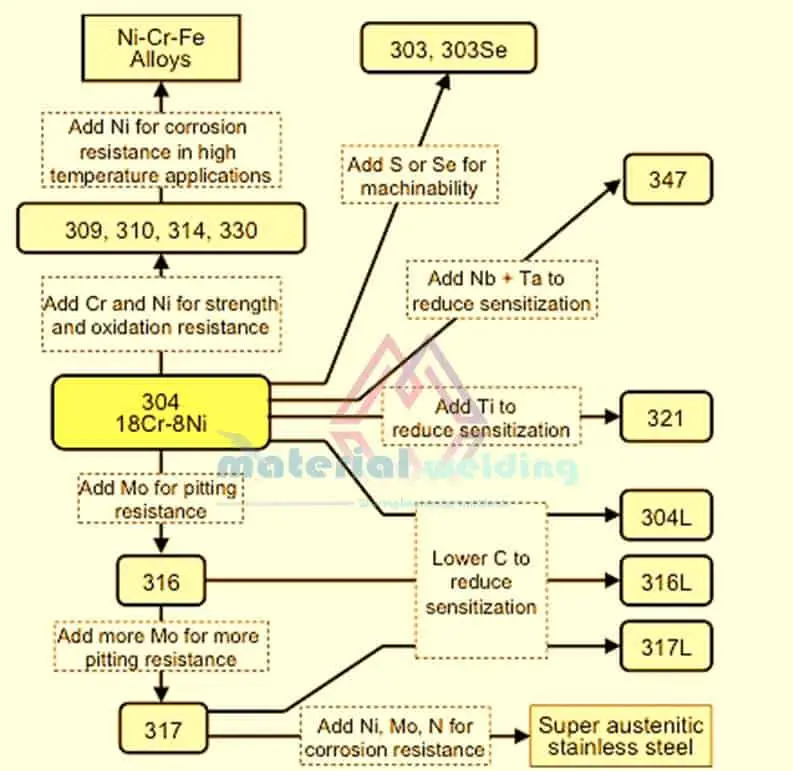

This article focused on 18/8 or 18Cr-8Ni steels generally called Austenitic Stainless steel. They are having tensile strength equivalent to mild steels, with approximately 210 Mpa (30 ksi) minimum yield strength at room temperature. They resist to hardenable by thermal transformation and offer very good sub-zero impact properties and weldability. They can be hardened by cold working and strength can be enhanced.

Types of Austenitic Stainless Steel

Austenitic stainless steels are classified as:

- 200 series and

- 300 series alloys by American Iron and Steel Institute (AISI).

200 Series has high carbon, manganese, and nitrogen compared to 300 Series & lower Ni to compensate for these elements. 200 series used in special applications e.g. application required galling resistance (Galling is a form of wear caused by adhesion between sliding surfaces e.g. wear at the bolt threads).

Further ASS grades are suffix with L (nominal value of 0.03 wt% C) or H (up to 0.1 wt% C) which mean low carbon or high carbon respectively. Grade 316 substitutes approximately 2% molybdenum (Mo) to a nearly equal amount of Cr to enhance pitting corrosion resistance. Some grades contain a higher amount of silicon and/or aluminum with carbon to maintain oxidation and/or carburization resistance and strength respectively.

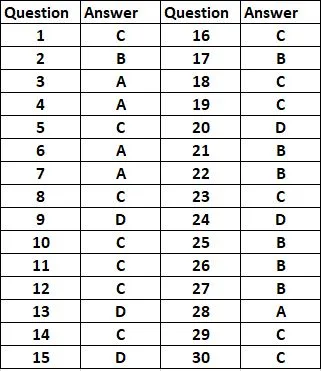

Austenitic Stainless Steel Stabilization Grades

The stabilized grades of ASS such as 321 and 347, contain a small amount of Ti and Nb, which are having higher carbide (MC-type) formation affinity to carbon compare to Cr at elevated temperature, thus preventing Cr-carbide (M23C6) precipitation. Austenitic stainless steels having up to 1% of Ti & Nb effectively reduce the matrix carbon content thus preventing M23C6 types formation. This also reduces the sensitization effect in ASS and hence prevents intergranular corrosion (IGC).

Austenitic stainless steels being ductile types exhibit significant elongation in a tensile test. The presence of Cr as a highly oxidizing element provides a protective surface layer for resistance against corrosion and further oxidation. They are not an appropriate choice in some common environments such as seawater, chloride-containing media or in highly caustic environments due to their susceptibility to stress corrosion cracking (SSC).

Alloying Elements in Austenitic Stainless Steel

In stainless steel materials, the addition of Chromium, Molybdenum, and Nitrogen improves the corrosion resistance for different types. Austenitic stainless steels cannot be hardened by heat treatment due to their non-responsive microstructure to heat. Although, austenitic stainless steel properties can be changed by work hardening phenomena without any loss in material toughness and ductility. Being an austenitic microstructure, austenitic stainless steel is a non-magnetic material. One of the main alloying elements i.e. Nickel improves the resistance to SCC or stress corrosion cracking failure mechanism. All the above super properties of austenitic stainless steel make it one of the very important engineering materials for various service environments.

In Austenitic stainless steels, nickel is the main element promoting the austenitic structure stability at the room temperature (generally over 8%) inter-alia to C, N, and Cu which also work as austenite stabilizers. Carbon also provides improved creep strength at elevated temperatures.

Nitrogen is added to certain grades as a strength enhancer mainly at ambient and cryogenic temperatures. Nitrogen added types are designated with suffix N e.g. 304LN. Manganese increases the solubility of nitrogen in the austenitic phase due to this higher N is added to grades having higher Mn%, especially in the 200 series.

Ferritic Stainless Steel

Ferritic Stainless Steel is a chromium-based stainless steel that falls into the ferrite family of steels. It has good formability and weldability, making it a popular choice for many applications. It also has high corrosion resistance and is often used in industrial, architectural, and transportation applications.

Ferritic stainless steel is a type of stainless steel that has a ferrite phase in its microstructure. This phase gives the steel excellent mechanical properties and resistance to corrosion. Ferritic stainless steels are available in a variety of grades to meet specific needs, each with different properties. Some common grades include 409, 430, and 442.

Martensitic Stainless Steel

Martensitic stainless steel is a type of stainless steel that contains high levels of carbon. This type of steel is known for its ability to harden quickly when heat is applied. Martensitic stainless steel grades are available in a variety of shapes and sizes, and are often used in the manufacturing of knives, tools, and medical equipment.

One advantage of martensitic stainless steel is its resistance to corrosion. In addition, this type of steel can be hardened to create a durable and strong product. Martensitic stainless steel is also magnetic, making it an ideal choice for applications that require a strong magnetic field.

There are a number of different grades of martensitic stainless steel available on the market today. Each grade has its own unique properties, so it is important to select the right grade for your specific application.

Duplex Stainless Steel

Duplex stainless steel is a type of stainless steel that contains both ferritic and austenitic stainless steel. Duplex stainless steel is more resistant to corrosion than other types of stainless steels, making it a popular choice for many industrial applications.

Duplex stainless steels are a type of austenitic stainless steel that have a higher corrosion resistance than standard austenitic stainless steels. This is due to the addition of molybdenum and/or nitrogen which form precipitates that inhibit corrosion.

Duplex stainless steel is available in a variety of grades, each with different properties. The most common grade of duplex stainless steel is S32205, which has excellent resistance to chloride-ion stress corrosion cracking.

Duplex stainless steels other main grades are, 2205 (S31803) and 2507 (S32750). Grade 2507 (S32750) has a higher chromium and nickel content than grade 2205 (S31803), making it more resistant to pitting and crevice corrosion. Duplex stainless steels are often used in applications where both high strength and high corrosion resistance are required.

Precipitation hardened (PH) Stainless Steel

Precipitation hardened (PH) stainless steel is a type of stainless steel that has been heat-treated to achieve increased strength and hardness. The increased strength and hardness are the result of precipitation hardening, which occurs when small alloying elements, such as chromium and nickel, precipitate from the austenite phase to form finely dispersed particles within the ferrite phase.

The precipitated particles are very hard and resistant to plastic deformation, which results in increased strength and hardness. Precipitation hardening can be achieved by heating the steel to a temperature above the eutectoid temperature (the temperature at which austenite transforms to ferrite and cementite), followed by quenching in water or oil.

There are several grades of precipitation hardened stainless steel available, each with different properties. For example, PH13-8Mo is a grade that is designed for high strength and toughness in applications where corrosion resistance is also required.

Ferritic Stainless Steel vs. Austenitic Stainless Steel

Ferritic and austenitic stainless steels are both iron-based alloys that contain chromium, but they have different crystal structures. Austenitic stainless steel has a face-centered cubic structure, while ferritic stainless steel has a body-centered cubic structure. This difference in crystal structure affects the alloy’s properties.

Austenitic stainless steels are more corrosion resistant than ferritic stainless steels. This is because the face-centered cubic structure allows austenitic alloys to form a protective oxide layer on the surface that prevents further corrosion. Ferritic alloys do not form this protective layer as easily, which makes them more prone to corrosion.

Austenitic stainless steels are also stronger and harder than ferritic stainless steels.

Difference Between Austenitic and Martensitic Stainless Steel

Austenitic and martensitic stainless steels are two of the most common types of stainless steel. They have different properties, which make them suitable for different applications. Austenitic stainless steels are more corrosion resistant than martensitic stainless steels because they have a higher chromium content.

Austenitic stainless steels are the most common type of stainless steel. These steels have a face-centered cubic (FCC) crystal structure and are non-magnetic. Austenitic stainless steels are generally corrosion resistant and have good mechanical properties. Martensitic stainless steels are less common than austenitic stainless steels and have a body-centered tetragonal (BCT) crystal structure.

Austenitic stainless steels are non-magnetic and have excellent corrosion resistance. They are used in applications where high strength is not required. Martensitic stainless steels are magnetic and have less corrosion resistance than austenitic steels. However, martensitic stainless steels typically have higher strength and hardness than austenitic stainless steels.

Martensitic stainless steel is often used for knife blades and machinery parts and other applications where a higher level of hardness is needed.

Stainless Steel Grades for Food

When it comes to food-grade stainless steel grades, there are three main options: 18/8, 18/10, and 304. All three grades have different levels of corrosion resistance, but 18/10 is the most resistant to corrosion. It’s also slightly more expensive than the other two grades.

18/8 is still a good option for food-grade stainless steel, as it has a moderate level of corrosion resistance. 304 is the most common grade of stainless steel, as it offers good corrosion resistance and a low price tag.

There are also other grades of stainless steel that can be used for food, but they may not have as much corrosion resistance. It is important to choose the right grade of stainless steel for your application, as different grades have different properties.

When it comes to food-grade stainless steel grades, there are a few important things to consider. The first is corrosion resistance. In order to ensure your food doesn’t come into contact with any harmful chemicals or elements, you’ll want to make sure your stainless steel has high corrosion resistance.

The most common grades used for food are 18/8 and 18/10, both of which have excellent corrosion resistance. Another thing to consider is the acidity of the food you’re storing. Acidity can cause stainless steel to corrode, so if you’re storing acidic foods, you’ll want a grade that’s specifically corrosion resistant to acids.

Most Common Grades of Stainless Steel

There are different grades of stainless steel, which are distinguished by their chemical and mechanical properties. The most common types of stainless steel are 304, 316, and 430.

304 stainless steel is the most versatile type and is corrosion-resistant against most chemicals. It is also tough and easy to weld. 316 stainless steel is more resistant to corrosion and has a higher melting point than 304. 430 stainless steel is less expensive than the other two types and has good formability but is not as corrosion-resistant.

Is 304 or 316 Stainless Steel Better?

There is a lot of debate over whether 304 or 316 stainless steel is better. Both have their pros and cons, but in the end, it comes down to what you are using the stainless steel for.

304 stainless is less expensive and more commonly used, but it is less resistant to corrosion than 316. In particular, it is susceptible to pitting and crevice corrosion in chloride-containing environments. 316 stainless steel, on the other hand, has better resistance to pitting and crevice corrosion, as well as to general corrosion.

However, 316 stainless steel is stronger and has better properties at high temperatures. So, if you are looking for a material that has good corrosion resistance and high strength, then 316 stainless steel would be the better choice.

However, 316 stainless steel is more expensive and can be more difficult to weld than 304. It also has lower strength than 304. So which type of stainless steel should you choose for your application?

The answer depends on the specific environment in which the metal will be used and the required level of corrosion resistance.

Stainless Steel vs Galvanized Steel

When it comes to choosing materials for your home, there are many factors to consider. Two of the most common materials used for homes are stainless steel and galvanized steel. Both have their pros and cons, but which one is the best for you?

Galvanized steel is coated in zinc to prevent corrosion, while stainless steel does not require any coating and instead relies on its own natural properties to resist corrosion. Stainless steel is also more expensive than galvanized steel.

When it comes to corrosion resistance, stainless steel is the clear winner over galvanized steel. Stainless steel is made up of several different alloys, including chromium and nickel, which make it more resistant to rust and corrosion than galvanized steel. In fact, stainless steel is so resistant to corrosion that it is often used in marine applications.

Galvanized steel, on the other hand, is only coated in zinc, which can easily corrode over time. This makes galvanized steel less durable and less resistant to weathering and rusting than stainless steel.

Stainless steel is also non-magnetic, meaning that it will not be affected by magnets. This makes it a good choice for appliances and other objects that need to be protected from magnets.

Stainless Steel vs Cast Iron

Stainless steel is a type of alloy steel that contains chromium and nickel. Cast iron is an alloy of iron and carbon. There are several important engineering applications in which stainless steel outperforms cast iron.

Cast iron is brittle and has low tensile strength, meaning that it can easily break or shatter when subjected to stress. Stainless steel, on the other hand, has high tensile strength and is much less likely to break or shatter. This makes stainless steel better suited for applications in which strength and durability are important, such as bridges, buildings, and machinery.

Cast iron also corrodes easily in the presence of moisture or oxygen. Stainless steel does not corrode as easily and therefore is better suited for outdoor applications or applications in which corrosion resistance is important.

When it comes to the debate of stainless steel vs cast iron for Kitchen Utensils, there are a few things to consider. Both materials have their pros and cons, but one may be a better fit for your needs than the other.

Cast iron is a heavy material that is good at retaining heat. This makes it great for cooking food over low heat or for dishes that need to be kept warm. However, because it is so heavy, cast iron cookware can be difficult to maneuver.

Stainless steel is a lighter material that doesn’t retain as much heat as cast iron. However, it is more durable and easier to clean. Stainless steel cookware also comes in a variety of shapes and sizes, making it versatile for any type of cooking.

Stainless Steel as a Conductor

Engineers have long searched for an alternative to copper wiring, as the metal is a great conductor of electricity. In recent years, stainless steel has been identified as a possible replacement.

Stainless steel is a good conductor because it is made up of tiny metal crystals that are able to move electricity easily. Additionally, it is durable and does not corrode, which makes it a good option for wiring in harsh environments such as marine applications.

While stainless steel wiring has not replaced copper wiring yet, it is being increasingly used in applications where its benefits outweigh those of copper.

Similar Posts

- AISI 304 Stainless Steel (18-8 stainless steel): The Facts You Need to Know

- The Properties of 316 and 316L Stainless Steel Explained

- Stainless Steel vs other materials-What are the advantages?

- Copper Sulfate Test for Iron Contamination in Stainless Steel cladding

- Why we can not cut stainless steel and aluminum by oxy-fuel gas torch cutting?

- How to Weld SS 321 Stainless steel, 321 to carbon Steel