What is Duty cycle for a Welder or Welding Machine?

In simple words, Duty Cycle in Welding for a Welder or Welding Machine refers to how long a welding machine will weld at a given current before it overload or overheat. Duty cycles are measured per 10 minutes and not for 1 hour or longer duration.

A machine if used with a 300 ampere current for welding @ 60% duty cycle will give an output of 300 amps for 6 minutes before overheating. So after, every 6 month machine requires 4 minutes cooling time and the machine can be used for 6 minutes every 10 minutes at 300 amperes.

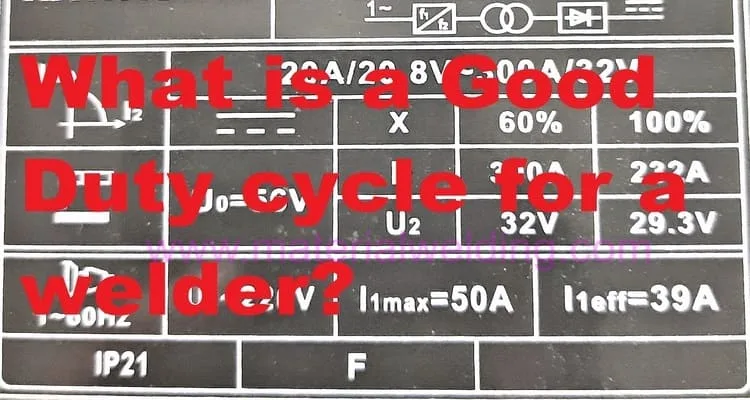

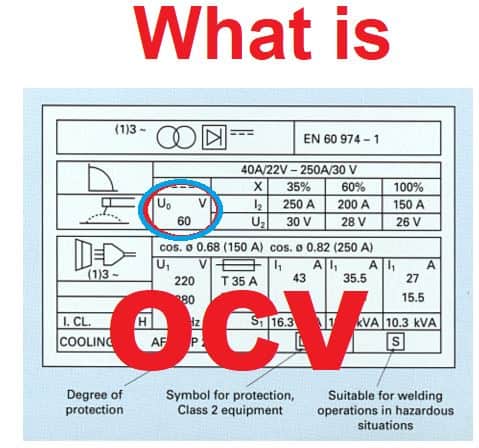

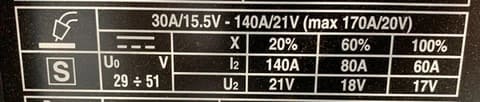

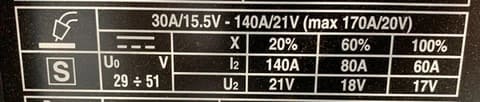

Refer to the below picture for a practical understanding. Here, based on the data from the nameplate or rating plate of the welding power source. The machine minimum output is 30A & 15.5V and the maximum is 140A & 21V.

So, the machine can give a maximum of 140 amperes current but if you wish to use this current the machine duty cycle is only 20%. This means, with 140A current, the machine can be run only for 2 minutes in every 10-minute cycle. The welding machine requires 8 minutes to cool down.

Similarly, the machine can be used for continuous operation with 60 amperes and 17V only.

As per the European Directive, number EN 60974-1, the time period for one complete cycle is 10 minutes.

Importance of Duty Cycle for Welder

Duty Cycle is spoken by most welding sales personnel and welding engineers while only a handful is aware of its actual meaning. So, understanding what it means, Its importance, and how it can affect a decision for welding machine purchase.

Related reading: Types of welding machines with pictures

While buying a new welding machine, understanding the importance of the duty cycle can save future maintenance costs, help to increase production, and avoid wrong purchase decisions.

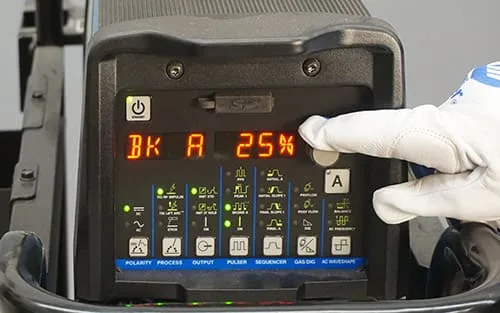

Duty Cycle is printed on the welding power sources nameplate (mostly front side or back side of the machine) and generally, you will see 20, 60%, and 100% duty cycles welding parameters.

Watch this video to learn how to read the Rating Plate or Nameplate of a welding power source.

Duty Cycle for MIG-MAG welding

MIG-MAG or GMAW Welding power source are rated at 60% duty cycle for semi-automatic operations and at 100% duty cycle for automatic continuous operation.

The automatic welding operations such as robotic welding needs 100% duty cycle as they requires continuous welding and there are no frequent breaks between welds as the weld route is planned.

How to calculate duty cycle in Welding of a welding machine?

Using this duty cycle formula you can find the duty cycle of a welding machine for an unspecified welding current & an unspecified duty cycle on the welding nameplate. Refer to the below formula for the duty cycle of a welding machine:

Duty cycle (%)= D/[( A/mA)*2]

- Where: A = Rated Current at the required Duty Cycle

- mA = Maximum Current at the required Duty Cycle

- D = Rated Duty Cycle [%]

Example for Welder Duty Cycle in Welding calculation

A power source having a duty cycle of 60% at a rated current of 200Ampere. What will be the duty cycle at 250 amperes:

Solution:

Using the formula Duty cycle (%)= ( A/mA)2 x D, we will have:

Duty cycle of: 60/[(200/250)2] = 37.5%

So, this formula is very helpful to find the value of the duty cycle for any unknown welding current which is not specified on the rating plate of the welding machine.

Meaning of 60% duty cycle in TIG/ MIG, FCAW, SAW & Stick Welding

The duty cycle in welding of 60% on the welder (machine) is most commonly highlighted by the machine manufacturer to show the maximum efficiency of the welding machine.

Assume, a machine if used with a 300 ampere current for welding @ 60% duty cycle will give an output of 300 amps for 6 minutes before overheating.

This must be followed by a 4 minute cooling time i.e. no welding for next 4 minutes out of 10 minute. So, the machine can be used for 6 minutes every 10 minutes at 300 amperes.

What is 100 duty cycle in TIG/MIG, FCAW, SAW & Stick welding?

The duty cycle of 100% on the welder is most commonly highlighted by the machine manufacturer to show the lowest efficiency of the welder.

Assume, a welder if used with a 60 ampere current for welding @ 100% duty cycle (shown in above rating plate) will give an output of 60 amps for continuous welding operation.

No cooling is required for welder during welding, the welder cooling system is able to keep the welder temperature within limit.

What is good duty cycle for welders?

First- Remember that duty cycle in welding is measured for 10 minute duration as explained earlier. Ideally, the best duty cycle for a welder is 100%.

This is required when doing MIG-MAG (especially robotic welding) or SAW welding as these welding processes use continuous welding operations.

Related Reading: What is a good duty cycle for a welder

So, welder (Welding machine) for MIG-MAG & SAW should be selected considering the range of welding current & voltage for 100% duty cycle.

Other hand, Stick welder (SMAW) and manual TIG welder does not have a continuous operations and requires frequent breaks for changing the welding rod, position and cleaning of welds (In stick welding). For these processes a welder with 60% duty cycle is good for most of uses.

How to Increase duty cycle of a welder?

Welder duty cycle is fixed by the machine manufacturer. It is not possible to change it as many internal machine components are designed accordingly , But however there are way to increase improve the welder performance.

The best way to work within the welder limits to avoid overheating and damage to it. But you can use water cooling welding torch, ensure the machine is kept in a well ventilated area & the cooling system of machine is regularly checked for its effectiveness.

Don’t use the welder is high temperature area as it will make it overheat fast.

Why must a welding machine duty cycle never be exceeded?

Running a machine more than the stated duty cycle can ruin the welding machine easily. Duty cycles are limit for a machine.

Using the welding machine above the stated rating will overload and overheat the welding machine. This will easily can burn the delicate electronic circuit of the machine. These electronic cards are quite costly and hence you will be billed for negligence.

Importance of Duty Cycle in Welding

The duty cycle in welding has a direct relationship with the ambient temperature of the welding power source. With the current advanced welding power source with sophisticated electronic circuits which need control on temperature for normal working, a higher ambient temperature can make big difference.

The duty cycle measured at 25 degrees and 40 degrees temperatures can be totally different as higher ambient temperature can interfere with the welding machine cooling system.

One must keep this in mind especially while making decisions in hot weather countries like in middle east, African countries, and some places in the USA. Knowledge of the Duty cycle in welding can impact the right selection of the welding machine.