Can you weld 316 with 308?

You can weld 316 with 308 welding rods in terms of weldability but you should not weld with 308 as it will affect the weldment properties of the welding joint. 308L welding rod is having low Molybdenum compared to 316 stainless steel. This will reduce its corrosion resistance as well there will be reduction in the overall strength of the weld compared to the base metal.

A welding joint made with 308 welding electrodes for 316 metallurgies will be having low amount of molybdenum. The PREN (Pitting resistance equivalent Number) of 316 is around 25-30% while the PREN of 308 welding metallurgy is only 20- 23%.

The reduced PREN is a major concern and will result in higher pitting corrosion in the weld metal compared to the base metal.

Hence, welding with 308 type welding wire or rod is not recommended for welding 316 stainless steel metallurgy.

What happens if you will 316 with 308 welding rod?

Stainless steel grade 316 contains molybdenum, which enhances its corrosion resistance (especially pitting resistance) capability compared to grade 304/ 308. Welds made using 308L/ 308 welding rod will have reduced amount of corrosion resistance.

In term of welding strength, both 308 and 316 stainless steel have same mechanical properties.

Best Welding rod for 316 stainless steel

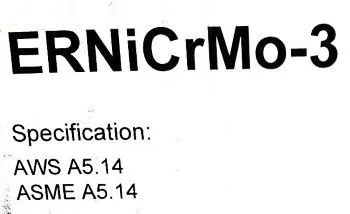

The best welding rods for 316 stainless steel welding are austenitic nickel-chromium wire such as ER316L or ER316LSi for TIG & MIG welding. Stick welding (SMAW) of 316 is best welded with E316L-15/16/17 rods. These rods are designed specifically for joining this specific type of stainless steel and gives good weldability.

Related reading: 316 Stainless Steel Welding Guide