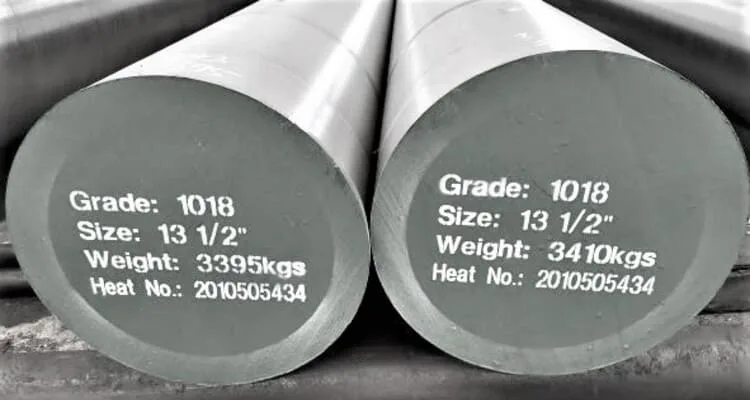

AISI 1020 steel

AISI 1020 steel is a low carbon, low tensile strength steel that has good machinability and excellent weldability.

It is commonly used in the manufacturing of parts that do not require high strength, such as gears, shafts, and bolts.

It is also used in the automotive industry for components such as gears, connecting rods, and hydraulic cylinders.

AISI 1020 steel standard

The UNS Number of AISI 1020 steel is G10200. ASME Section IX P Number for 1020 steel is P Number 1 & group no. 1.

The chemical and mechanical properties of AISI 1020 steel are defined in the ASTM A108, A 513 A519, and A576 standard.

Other standards for AISI 1020 steel delivery are:

- AMS 5032, 5045,

- BS 970: 040A20 and 050A20 (En2C).

- DIN 1.0402.

AISI 1020 steel chemical composition

AISI 1020 steel chemical composition are:

- Carbon: 0.17-0.23%

- Manganese: 0.30-0.60%

- Phosphorus: 0.040% max

- Sulfur: 0.050% max

AISI 1020 steel mechanical properties

AISI 1020 steel mechanical properties are:

- Yield strength: 50.8 Ksi (350 MPa)

- Tensile strength: 61 Ksi (420 MPa),

- Elongation: 25%,

- Hardness: 126 HV (68 HRB).

AISI 1020 steel weldability:

AISI 1020 steel can be welded using all welding techniques. It is best to preheat the thick steel before welding and to use low hydrogen electrodes. Small thickness does not require any preheating.

Stick welding can be done using E7018 rods while ER70S-2 is good for TIG welding.

AISI 1020 steel heat treatment:

- AISI 1020 steel is not heat treatable. Carburizing is the possible heat treatment although.

- Stress relief annealing if required can be carried out at 600°C.

AISI 1020 steel Uses:

AISI 1020 steel is used in the manufacturing of parts that do not require high strength, such as gears, shafts, and bolts.

It is also used in the automotive industry for components such as gears, connecting rods, and hydraulic cylinders.